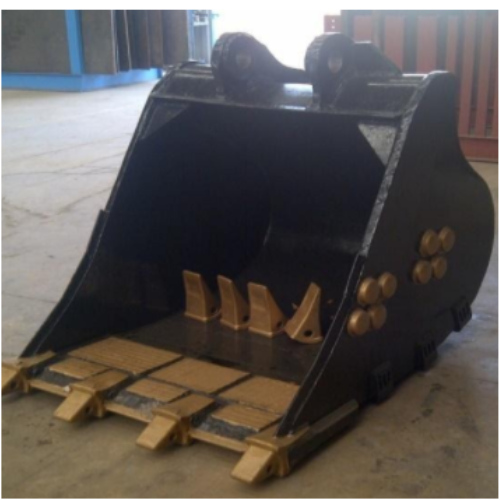

Bucket Protections kits

Overview

We offer various components which act as bucket protection kits.

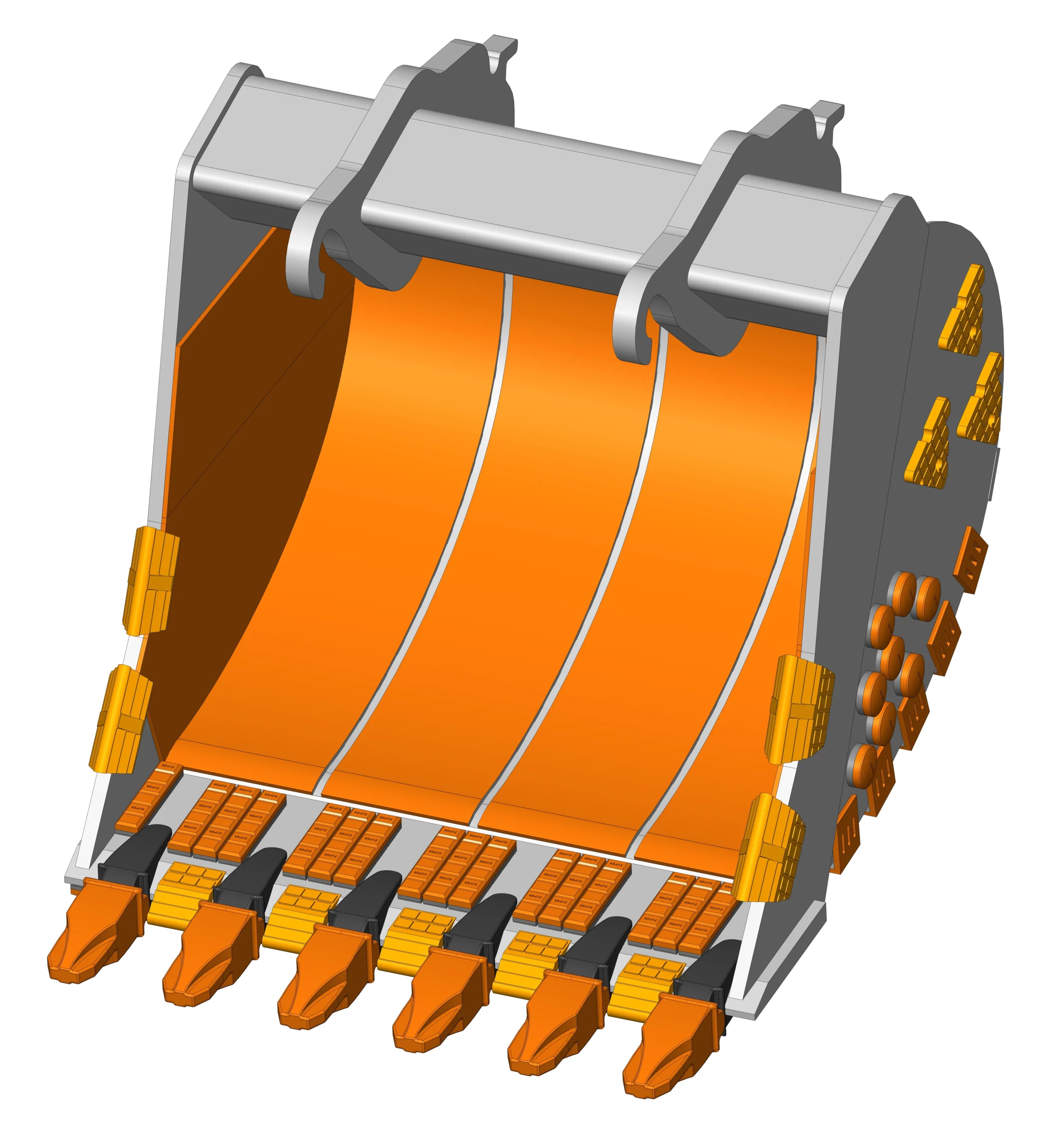

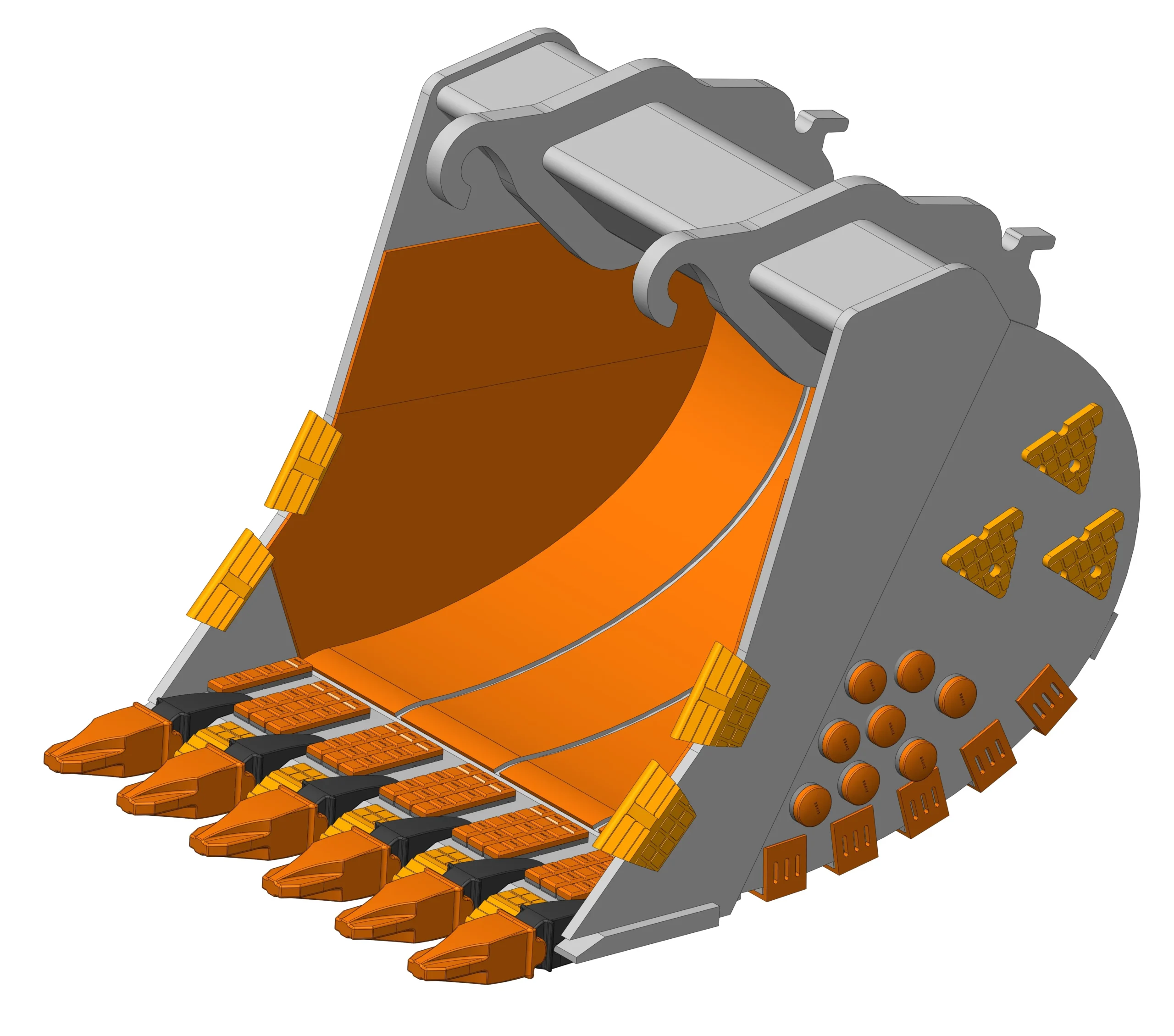

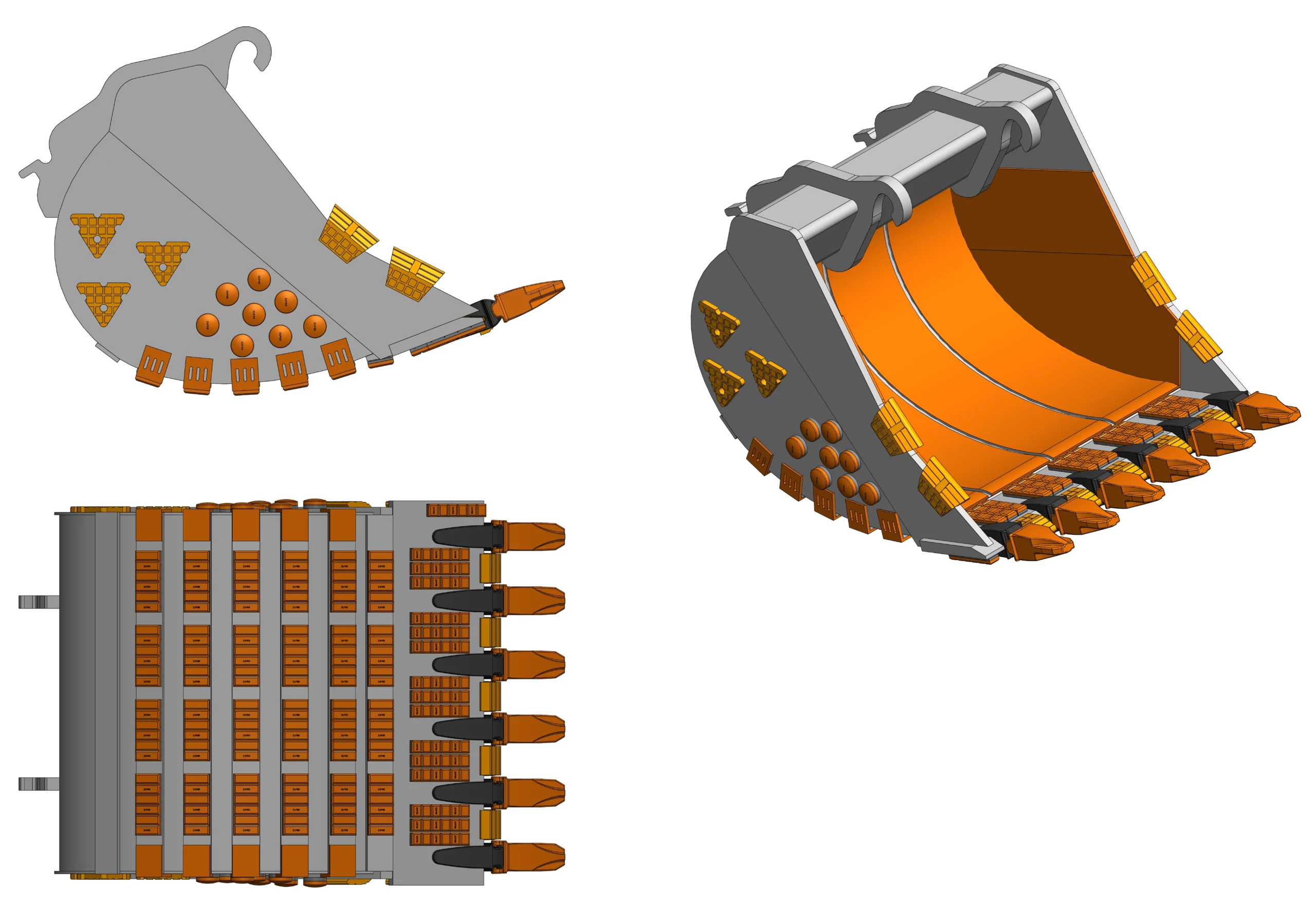

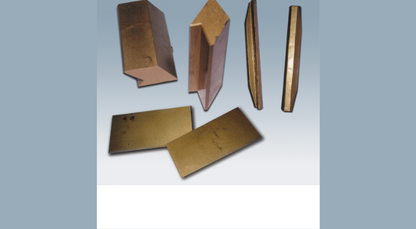

Zuper choko

Hyper eutectic composite carbide metallurgically bonded to a mild steel backing plate. This combination of with minimum hardness of 770 hv and carbides upto to 1500 gives you a very high abrasion & impact resistance properties.

Zuper chocos are mainly used on the bottom of the excavator bucket to withstand heavy impact & sliding abrasion. The backing plate gives you the ability to form and weld the blocks onto curved or flat surfaces.

IMCO is committed to provide the highest quality products and services, conduct supervision, guiding upon the exact configuration procedures to reconditioning buckets in the right and cheapest method and of highest international quality. These methods will save lots of down time, labour, money and top it with highest working life compared to any other conventional costly hard facing welding.

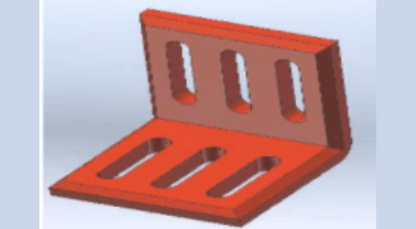

Choko Blocks

Part no | Length | Width | Thickness | Weight (Kgs) |

Zuper CB-25 | 240 | 25 | 23 | 1.05 |

Zuper CB-40 | 240 | 40 | 23 | 1.78 |

Zuper CB-50 | 240 | 50 | 23 | 2.12 |

Zuper CB-60 | 240 | 65 | 23 | 2.83 |

Zuper CB-80 | 240 | 80 | 23 | 3.75 |

Zuper CB-90 | 240 | 90 | 23 | 4 |

Zuper CB-100 | 240 | 100 | 23 | 4.25 |

Zuper CB-130 | 240 | 130 | 23 | 5.56 |

Zuper CB-150 | 240 | 150 | 23 | 6.45 |

Applications

- Bucket

- Gyrator

- Cone crusher

Zuper Buttons

A modified abrasion resistant composite consisting of carbides in a metallic matrix, metallurgically bonded to a mild steel disc. The carbides have minimum hardness of 770Hv and contain carbides up to 1500 Hv.

Zuper buttons are designed circular and dome shaped to minimise the effects of heavy impact and resist high stress, abrasion & erosion.

These are mainly used to protect the bucket from all the sides, adaptor area are easy to weld as these are also available in sheets in which the buttons are fitted as per your contour.

Various sizes of zuper button

Part no | Diameter | Thickness | Weight |

Zuper 50 D | Dia 50 | 24 | 0.33 |

Zuper 60 D | Dia 60 | 27 | 0.6 |

Zuper 75 D | Dia 75 | 27 | 0.83 |

Zuper 90 D | Dia 90 | 27 | 1.4 |

Zuper 90 D | Dia 90 | 32 | 1.51 |

Zuper 101 D | Dia 101 | 31 | 1.75 |

Zuper 110 D | Dia 110 | 32 | 2.4 |

Zuper 115 D | Dia 115 | 32 | 2.7 |

Zuper 150 D | Dia 150 | 41 | 5.8 |

Lip Guard

Without lip guard the leading edge of the bucket is exposed to constant abrasive wear. Hardened chrome steel with a hardness of 40-44 hrc protects the leading edges of the bucket from becoming round.

Zuper Heel Guard

Zuper Heel guards are designed to protect high wear areas, such as the corner edges on excavator, loader and face shovel. These hardened chrome steel heel guards have a hardness of 45-50 Hrc and provide superior wear protection when placed on the outside radius of the bucket.

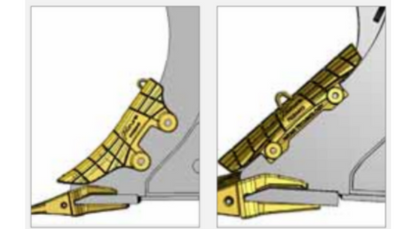

Weld on Side Cutter

Zuper hardened steel side cutters are designed to protect buckets in the front cutting edges and protect the base material of the bucket. These can be easily bolted on the sides of the bucket.

Teeth

Toothpoint is designed for maximum strength and impact absorption, this breakthrough engineered skills delivers speedy installation and pin retention. These wear parts let you work smarter and increase profits by slashing machine downtime.

Zuper EDP 21 plates

The conventional straight bead wear plates when exposed to extra fine earthly materials can suffer from major linear wear that causes premature failure. In case of zuper 21 (EDP) plates, overlay weld beads are in a weld pattern with specified directional changes. This ensures superior wear resistance against erosion. These plates have a hardness of 60-64 hrc. Areas between the tooth points are protected against wear and tear with these plates.

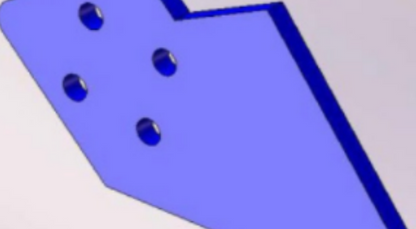

Shoulder Shrouds

Similar to lip guards, shoulder shrouds protect the cheek plates of excavator buckets. IMCO offers a large selection of vertical shrouds with different styles and sizes to match a wide range of equipment.

Through Extreme research it has been observed that direct inserts of wear resistant material offer better wear resistance than hard facing. Advantages of Zuper wear protection kit are:

Key Benefits

- No high stresses developed on the base metal

- Superior metallurgy for better wear resistant

- Easy to install and maintain

- Higher thickness of wearing part of up to 10 mm as compared to max 5 mm of hardfaced welding for better wear resistance

- Huge savings in labor and welding cost

- No inventory of welding electrodes required

- Reduced downtime

- Increased productivity