Cement Products

Keeping in line with the technological advancements, the Cement industry has transited itself into a more advanced technological and competitive gamut .Impact, corrosion and abrasion are the major wear problems in this sector due to the presence of heavy metals/abrasive components in the natural raw material and from the use of recycled by-products or alternative fuels.In addition, the high temperatures and harsh environments found in cement production can also contribute to wear and tear. To mitigate these effects, cement companies may use wear-resistant materials and coatings, as well as regular maintenance and replacement of worn components.

IMCO prides itself on its contribution to provide high quality indigenous Zuper products to Cement industry, which not only enhances the life of critical applications but also provides better efficiency, performance and substantial cost savings. Our product range includes Crusher Hammers, Beater Head and Arm, Grinding Rolls for VRM, Dam Rings etc. and is a renowned manufacturer of wear resistant products for this industry. We are also capable of designing, developing and manufacturing any custom made products for this industry depending on the wear patterns of critical applications thereby saving huge costs and economic losses to the factories. For more details, you may visit our products segment.

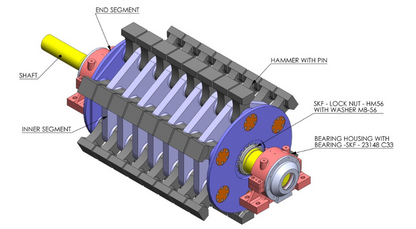

Hammer Crusher Rotor Assembly

Rotor Assembly consists of various parts such as hammers,rotor discs, Main shaft, Flywheel, Bearings ,Bearing housing, axle pin etc. our company manufactures to enhance

Limestone & Clinker Crushing Hammers

Clinker and Limestone can severely wear on impact bars and crusher hammers. Conventional hardfacing welding leads to huge stresses and heat affected zones

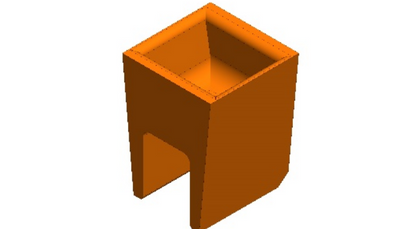

Dip Tube

The Imco make Dip tube is a Hi Nickel casting duly coated with Amorphous powder coating that can withstand in 1100 - 1200 Deg. C temperature, high abrasion and corrosion. Dip tubes have a crucial influence on the separation efficiency.