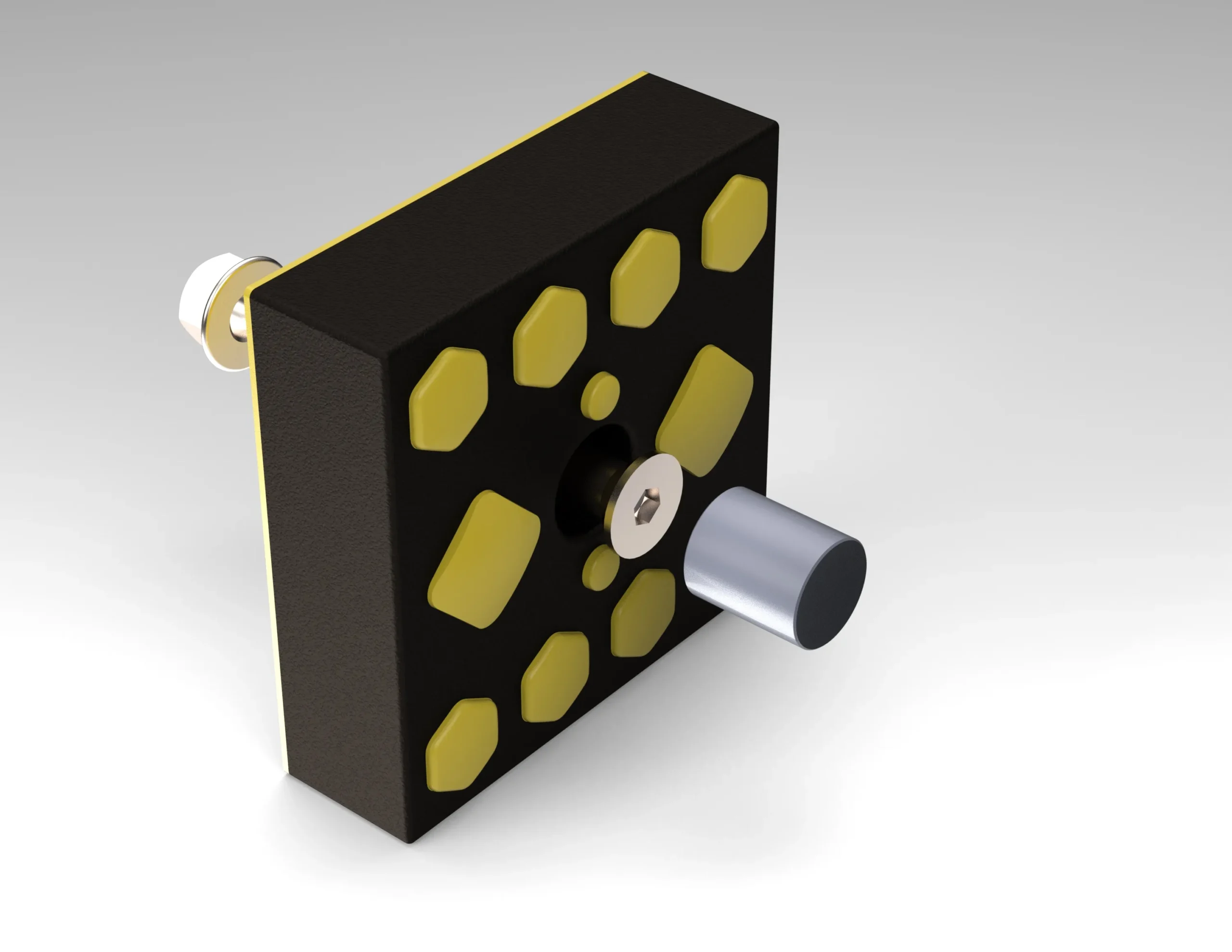

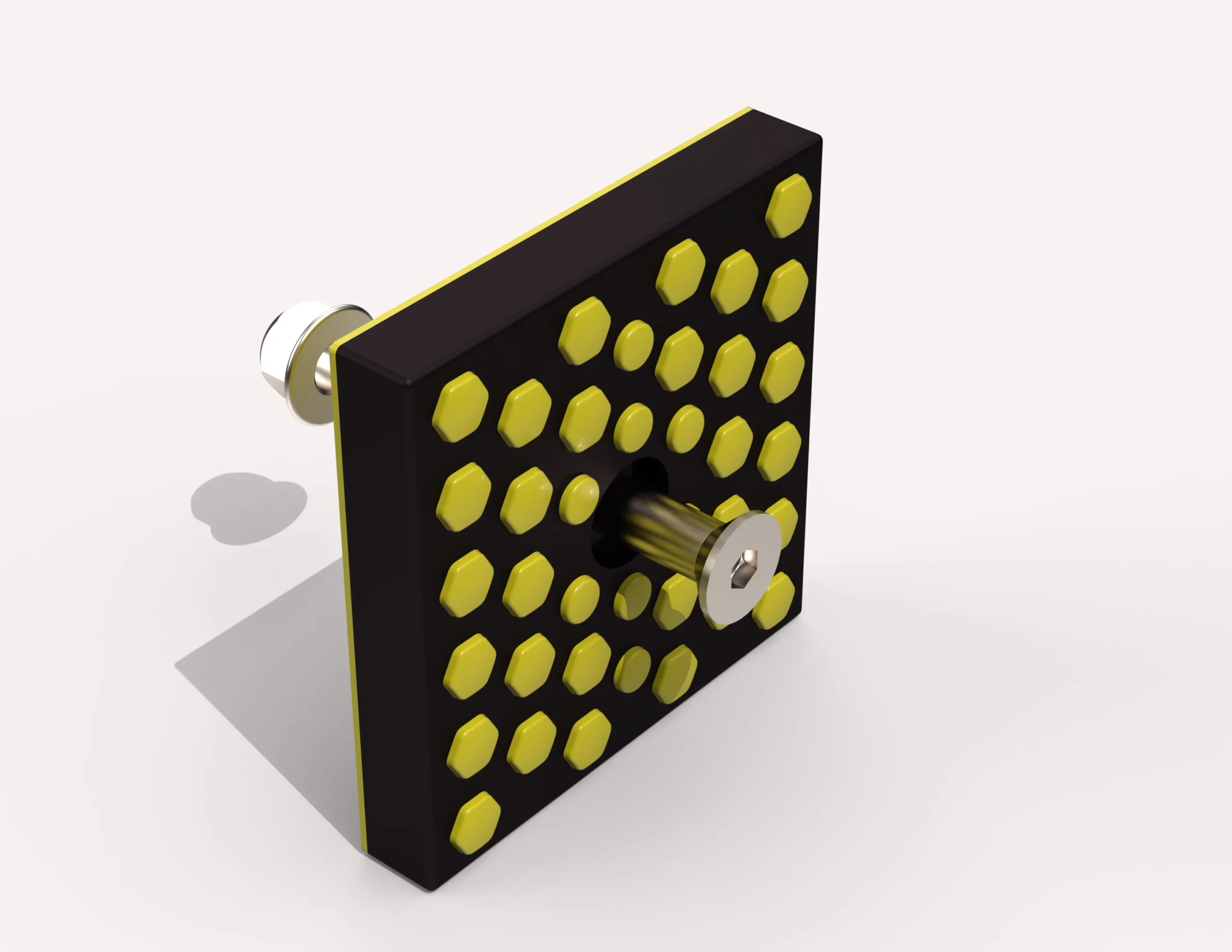

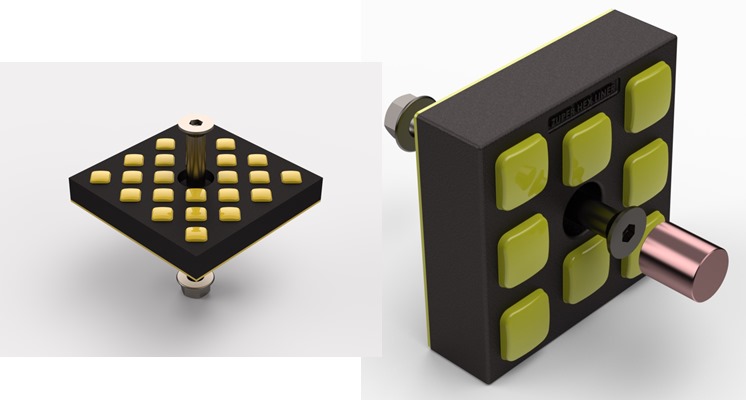

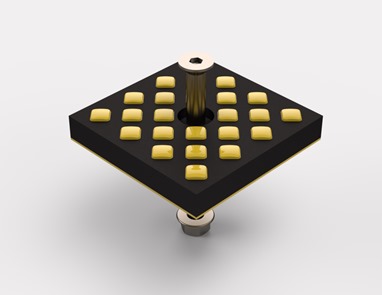

Revolutionary IMCO Zuper Hex

Overview

Zuper Hex is extremely strong abrasion resistant composite metal matrix carbide cermets, fixed to a mild steel backing plate. These carbides have a minimum hardness of 1100 Hv to 1500 Hv and can withstand extreme abrasion, erosion wear and high temperature.

Sand, silica and other abrasive materials like feldspar, quartz, dolomite, bauxite, copper-ore, nickel, etc. carry forwarded during mining can cause severe wear in all conveyor systems, bulk handling system, transfer lines, chutes, bunkers, all types of rotary equipments (ball mills etc). Replacing these parts with the Zuper Hex can sustainably reduce the wear giving considerable savings and reduction in the downtime.

Repeated welding leads to huge stresses and heat-affected zones. Zuper hex is the most cost effective replacement available which is fitted with a single bolt or welded to the base. These liners can easily be replaced, giving a longer life and reducing power consumption.

Zuper Hex is the world’s most cost effective and time saving method compared to any hardfacing welding / cast liners.

Note: The Zuper hex liners are available in standard sizes. Also, customize sizes are available as per the clients requirement

| Properties | Measurement |

| Density of Cermets: | 3.5 – 4.5 g/cc. |

| Hardness: | 750 – 900 Vickers hardness |

| Max working Temperature: | 700 – 900° C |

| Flexural Strength: | 120 – 130 ksi |

Major Application of Zuper Hex for high Abrasion/ Impact Applications

Chutes

Hoppers and bins

Feed / Stone boxes

Mining and Cement industries

Cutting Edge Design

- If a standard plate does not exist on the shelf to suit your particular application, we will design and manufacture as per your requirement. Our manufacturing facility operates on a fully accredited quality system. Our strict quality control is guaranteed by our team of Engineers, which operates on a continuous Research & Development to provide our customer a global product.

Network

- Our distribution network and supply chain extends to the industries all over India and abroad through our highly professional team of Engineers working round the clock for customer satisfaction. We also extend our chain of authorized stockists serving extensively to fulfill the needs of customers from product design, production, supply and after sales services.

Key Benefits

- Extremely strong abrasion resistant composite

- Easy replacement process which saves downtime

- Longer life span of the products

- Less energy utilizations