Revolutionizing Pinion Reconditioning: IMCO’s Zuper W 503 OA Streamlines Repair Processes

Within the realm of industrial maintenance, certain tasks have traditionally been seen as unavoidably time-consuming and costly. One of these, without a doubt, is the process of repairing pinions. The conventional approach utilizes a 4mm stick electrode, a method that has endured for years despite its inefficiency.

However, we at IMCO believe in challenging the status quo, seeking innovative ways to redefine the standards of our industry. We are proud to introduce our breakthrough solution, the Zuper W 503 OA, a product set to streamline and revolutionize pinion reconditioning.

The Zuper W 503 OA Advantage

Zuper W 503 OA is a groundbreaking open arc flux-cored wire that is created from a harder and tougher material than conventionally used. When applied to worn-out pinions, it serves as a vastly superior solution, increasing efficiency and, as a result, saving considerable time and money.

One of the unique characteristics of Zuper W 503 OA lies in its composition. It is both harder and tougher than the material traditionally used for pinion repair. This makes it ideal for the strenuous task of reconditioning pinions, which are often subjected to high levels of stress and wear.

Innovative Reconditioning for Improved Performance

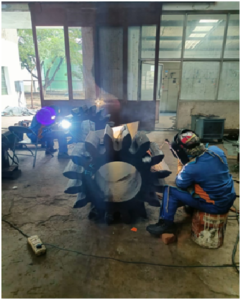

The application process of Zuper W 503 OA is equally significant to its effectiveness. The open arc nature of this flux-cored wire guarantees superior coverage and deeper penetration than the conventional 4mm stick electrode.

Furthermore, rebuilding the teeth of pinions using this state-of-the-art wire involves a refined, precise technique. The selection of the appropriate electrode coupled with this advanced method results in reduced wear and tear. The result is a more durable and longer-lasting pinion, saving businesses from frequent and costly repairs.

Cost-Effective, Efficient Repair Process

The use of Zuper W 503 OA in pinion reconditioning enables businesses to transform a traditionally expensive, time-consuming task into a more efficient, cost-effective process. By reducing both the time taken for the reconditioning process and the cost associated with it, businesses can achieve significant operational and financial benefits.

Moreover, by increasing the lifespan of pinions and reducing maintenance downtime, the operational availability of machinery is significantly enhanced. This increased productivity and reduced interruption can make a substantial difference to business operations.

More than a Product – A Solution

In essence, Zuper W 503 OA represents more than just a product; it is a clear demonstration of IMCO’s commitment to providing solutions that genuinely make a difference to our customers. It is the recommended choice for any businesses looking to optimize their pinion reconditioning processes.

At IMCO, we understand that every business has unique needs and challenges, and we strive to meet these through our innovative solutions. Contact us today to find out more about how Zuper W 503 OA can revolutionize your pinion reconditioning process. At IMCO, we deliver more than products – we provide solutions that save time, increase efficiency, and drive your business forward. Experience the difference with IMCO today.