About- Condition Monitoring Systems(CAM)

1. I & A ( Inspection & Analysis) of all critical Mill parts

2. Recommendations & report submissions:

3. R&R: Reconditioning and /or Replacement job :

4. Re-Installation of equipment:

5. Installation & Commissioning & calibration of thresh-hold values:

6. Real time monitoring at given frequency

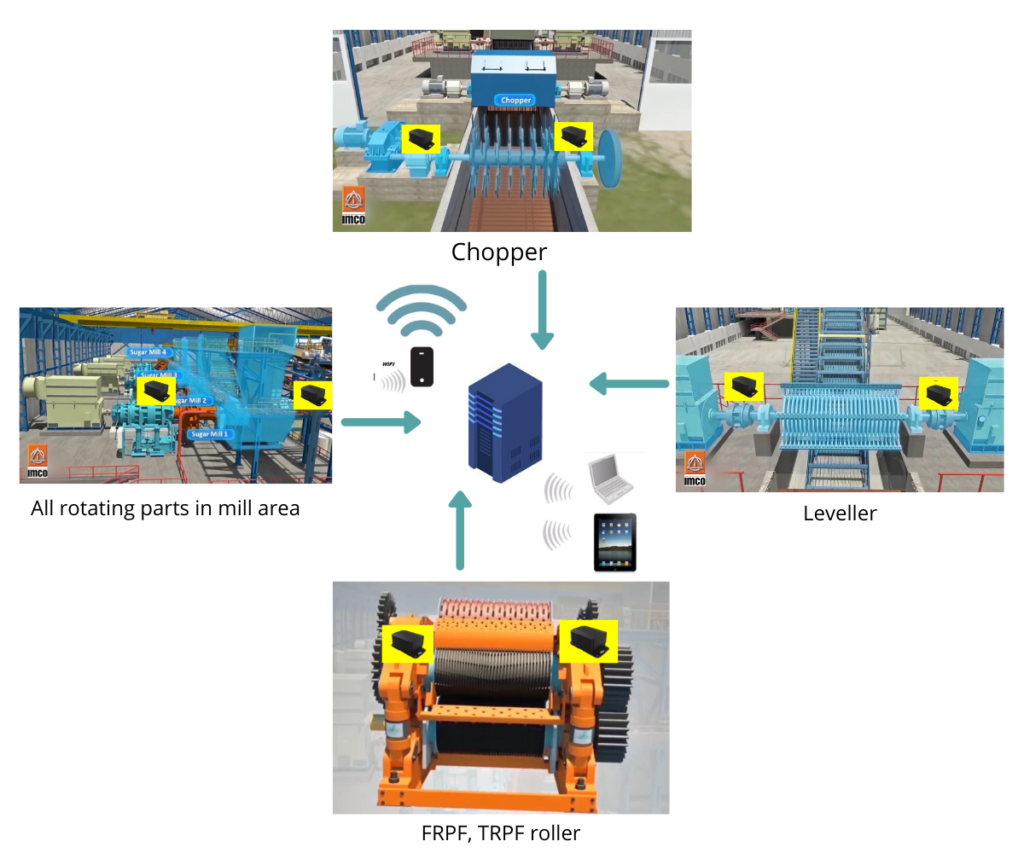

Predictive Maintenance for Rotating Equipment

Problem

- No access to real-time insights on vibration of rotors

- No access to full life cycle and remote monitoring for predictive maintenance.

- Threshold values - No real time alerts in case the threshold values are breached

- Unscheduled downtime and breakdown

Solution

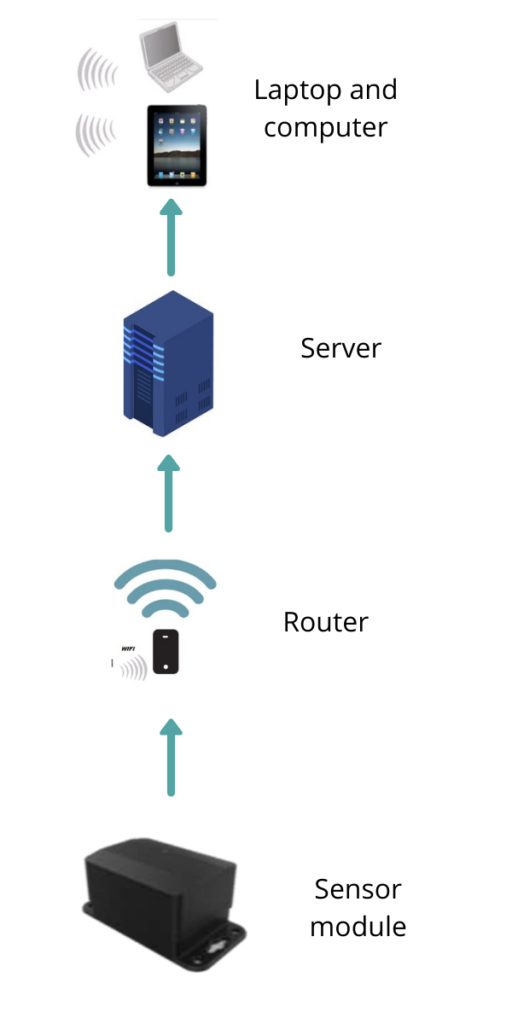

- COINs are installed on machinery from which insights are required.

- Temperature and Vibration sensors in COIN will record any irregularities (upper and lower threshold values) at regular intervals and shares this data real-time over the cloud via our Wi-Fi or Ethernet gateway.

- The manual process of monitoring the health of machines every 15 to 20 days is eliminated using our solutions

- We can analyze historical data to identify the root cause and location of frequently occurring issues.

Benifits

- Predict asset failures in advance (FFT)

- 100% uptime without breakdown

- Periodic reports for better planning

- Higher Productivity

- Lower Operational Cost & Economical

Coin- Our Flagship Product

- Communication speed - 1 Mbps. Suitable for high speed & high data applications. Self-learning and self-healing capabilities.( out of network if the battery is down for whatever reasons the system reconnects by the shortest avl route- keeps on hunting.

- Self Healing- the coin that was down will start and hunt and self heal on its own.

- Range - 180 ft per node max subject to interference. Range increases with more nodes in the mesh. ( coin to coin is node to router) if coins are not able to connect to the gateway the additional coin will act as a booster.

- Machine learning and edge computing on every node. Studying vibration patterns to formulate with algorithms will keep on comparing and if the difference is within range). Edge computing is a processing happening on every coin – load . This reduces lag.

- D type battery

Advantages Of Condition & Monitor

- Avoid breakdown.

- Predict failures in advance.

- Get periodic reports for better planning.

- Get higher productivity.

- Lower operations and maintenance cost.

- Keep your plant perfect.

Benefits | Features | Advantages |

No Need of Maintenance, Calibration | Calibrated for life | No downtime, No periodic service |

Readings in Deg Celsius or Fahrenheit | Units as per your needs | Easy readings |

No data Loss in case of power down | COIN + Gateways has onboard flash memory | Always stay connected to machines |

Wide Temp. range of operating conditions across winter/ summer | Temp from -40 to +80 Deg C | Any existing + other machines operating in other conditions can be covered. |

% RH wide range in Winter & summer | % RH from 0-95% | Any existing + future machines can be covered ( RH will be measured within an area covering 1-3ft in radius from the sensor). |

Will cover all your vibrations patterns | Vibration – from 0 to 16 g (m/s2) available, can give Velocity, Displacement, Acceleration | No need to have additional sensors/ Hardware ( velocity of vibration (time required),displacement ( height of the vibration),Acceleration (G value) |

Always up to date software | Can be updated via internet Hardware has onboard microprocessor + | Cutting edge technology in Industry 4.0 |

Remote connected | Hardware has onboard microprocessor + Networking ability |

|

Wifi +Ble

- The gateway used is a Wifi +Ble gateway.

- Ethernet +Ble gateway (coin to gateway)

- To be used only if the facility does not have Wi-fi, does not permit or restrict the use of Wi-fi

- Our Ethernet gateway can also store data on the cloud server.

Deliverables :

The Following Will Be The Added Benefits:

- Separate account with Login + Password

- Browser based access to multiple devices

- Cloud Storage

- Cloud Analytics.

- SMS, Email notifications as per threshold

- Every end of the day automatic report.

- Remote technical support

- User settable threshold setting etc.

Sensor

- No calibration or maintenance required.

- Easy readings.

- Wide operating temperature

- Great communication speed.

- Wide range of humidity monitoring.

- Covers all vibration patterns (velocity displacement and acceleration)

- Latest technology ( Industry 4.O)

- User settable threshold setting etc.

- Battery life: 1 year.