Maintenance & Repairing Services

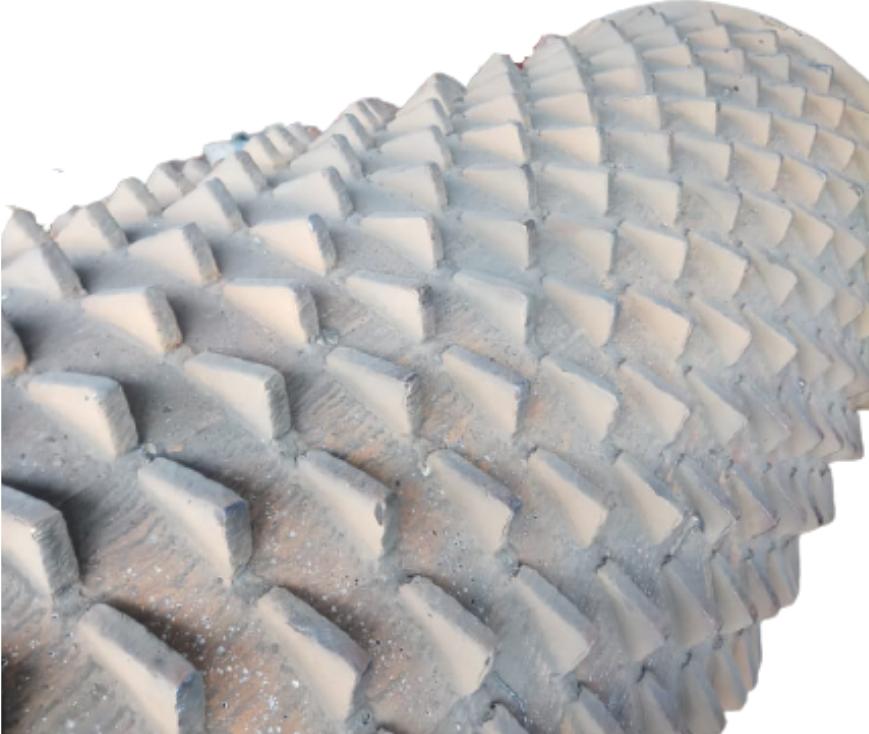

With Decades of first-hand experience in development and working in close collaboration with the leading Sugar factories, we’ve developed a unique product portfolio for the Sugar industry. Our portfolio for M&R in the sugar industry include metallurgically demanding welds like in our patented Zuper Teardrops on Rollers, TRPF repair, Pinion welding, etc. Our team of specialised workmen and products have proven quality and excellent welding training which are valued all over the world.

Our Welding consumables are used in numerous demanding areas of the Sugar Manufacturing industry, e.g., in Roller Arcing, Pinion Welding, Roller Journals, and multiple Hardfacing applications. Our new generation of flux cored wires has already been successfully applied by notable branch leaders and enables the highest process reliability.

IMCO Mac series

Pinion Reconditioning

Conventional method of repairing pinions using a 4mm stick electrode is time consuming.

We at IMCO use the Zuper W 503 OA, an open arc flux cored wire that is made of a harder & tougher material which when applied on worn out Pinions is the most efficient way to save time and money.

The teeth are rebuilt using the right technique and the appropriate electrode which helps reduce wear.

Wear Protection Of Trpf Roller

TRPF rollers are mainly used to enhance the crushing capacity, adding a number of compression and making proper even blankets to feed to the conventional mill. During the operation, TRPF drum and it’s teeth gets worn-out due to abrasion, corrosion and Erosion

The Present Solution of using a 4mm rod is time consuming and costly while offering only 60% product efficiency. The IMCO solution is using the Zuper W 530 OA, a open arc flux cored wire offering a hardness of 58-60 Hrc. The wire enables The wire enables continuous welding while offering an unmatched 90% product efficiency thereby saving time and money.

Reconditioning Roller Journal

Roller Reconditioning, Arcing And Ztd

Scrapper & Trash Plates

Hardfacing On Hammer Body & Knife Body

Repairing Worn Out Anvil

Anvil is generally pocketed and requires high hardness in order to resist the heavy impact and abrasion of cane at a speed of 780-800 RPM.

Wear occurs in Anvil due to 1.Heavy impact abrasion 2. The clearance between Anvil and hammer is small 3. Erosion due to silica & 4. corrosion due to the acidic nature of sugar juice.

Do full welding using Zuper R 650 or use readymade Zuper Bar that can be fitted easily on ribs

IMCO Solutions

1. Welding with hard facing electrode and rebuilding the working area where these wear problems occur.

2. Checking the condition of SS/ gun metal bush and replacing it, if worn out.

3. In Fixed Type Leveller, Checking the condition of the bore and rebuilding it.