Zuper Hi-Life Liners

Overview

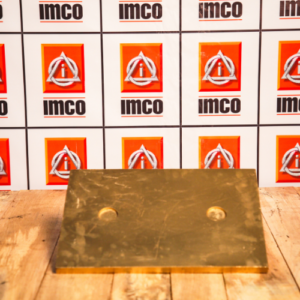

IMCO makes Zuper Hi-Life a solution for various high abrasion wear issues that rise in chutes, hoppers, feeders, bins, etc. by increasing the life of

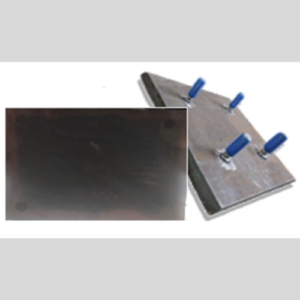

mechanical equipment by shielding its surface. Our Revolutionary “ Zuper Hi-Life “ Wear Liner which has High Density and Ultra-abrasion Resisting Carbide composite (60-62 HRc) metallurgically fused to a mild steel backing through our patented process. (Can also be offered without a base plate for low-impact areas).

| Hi Life with Base plate (21 mm thk and above) | |

| L | W |

| 100 | 100 |

| 150 | |

| 200 | |

| – | |

| 200 | 150 |

| 200 | |

| 250 | |

| 300 | |

| 250 | 150 |

| 250 | |

| 300 | |

| 300 | 200 |

| 300 | |

Cutting Edge of Design

If a standard plate does not exist off the shelf to suit your particular application, we will design and manufacture to your requirement. Our manufacturing facility operates a fully accredited quality system. Our strict quality control is guaranteed by our team of Engineers, which operates on continued Research & Development to provide our customer a global product.

Network

Our distribution and supply network extends to sugar, Cement, Power industries all over India and abroad through our highly professional team of Engineers working round the clock for your satisfaction & customer services through our chain of Authorized stockiest servicing extensively to the need of the customer from product ,design, production, supply after sales back up into our customer hand.

Major applications

- Feeder Hi life Liners

- Chute Hi life Liners

- Mill Body Hi life Liners.

- Carbide Hopper Hi life Liners

- Gyratory crusher

- Iron ore hopper

- Lignite hopper

Key Benefits

- Low Coefficient of friction (~ 45% lower than SS/Hardox) in service.

- Reduced hang-ups & carry backs.

- Max Wear Resistance irrespective to the direction flow of abrasive particles.

- Hexagonal carbides offering unsurpassed wear resistance

- Laminar flow ensuring reduced wear

- NIL Dilution - unmatched wear resistance

- Consistent Hardness & Micro-structure across thickness results in consistent & unmatched wear rates

- Process ensures Extremely Low Residual Stress

- Packed & Uniform Distribution of superior Hexagonal primary carbides improving wear