Power Products

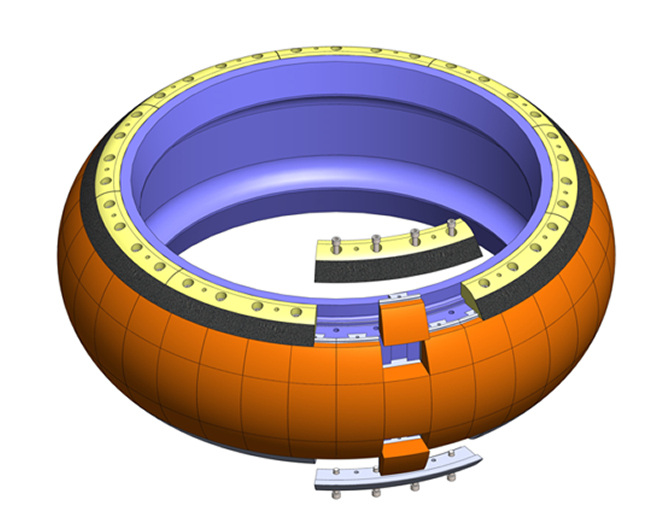

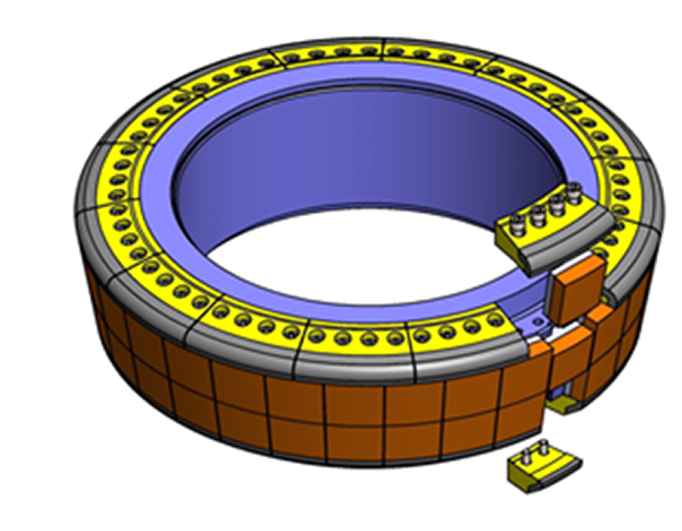

Zuper MMCC grinding roller with fully replaceable segments

Overview

Our replaceable grinding roller tires are engineered to deliver exceptional performance and longevity in demanding industrial applications. they combine high wear resistance, superior & strength. The segment-based replaceable design ensures easier maintenance, reduced downtime, and lower operating costs, while consistently delivering efficient grinding performance.

1A) Zuper MMCC grinding roller with fully replaceable segments

ZUPER Metal Matrix Ceramic Composites are extremely strong abrasion resistant carbides metallurgically bonded to replaceable segments. These carbides have a minimum hardness of 770 Hv and contain carbides up to 1500 Hv most commonly used in Coal Plants globally. These extremely level replicable carbides are very easy to use and can be replaced in a very short period of time. Zuper MMCC Rollers are the most cost effective VRM and Coal Mill grinding rollers in the whole world. Our planted innovations in the metallurgy segmented make these rollers more resistant to wear as compared to traditional rollers.

Know the Benefits

- Most cost effective solution

- Most advanced Metal Matrix Carbide Composites

- Maximum Wear & Abrasion Resistance

- Reusable Mother core/ tires.

- Easy replacement process. Hence reduces maintenance cost

- High Grinding efficiency in Coal Mill

- Saves downtime and production cost

- High tensile bolt for a longer life span

IMCO Alloys & Co. KG © 2022

Data Protection Imprint and legal notice