Zuper Metal Matrix Carbide Composite

Overview

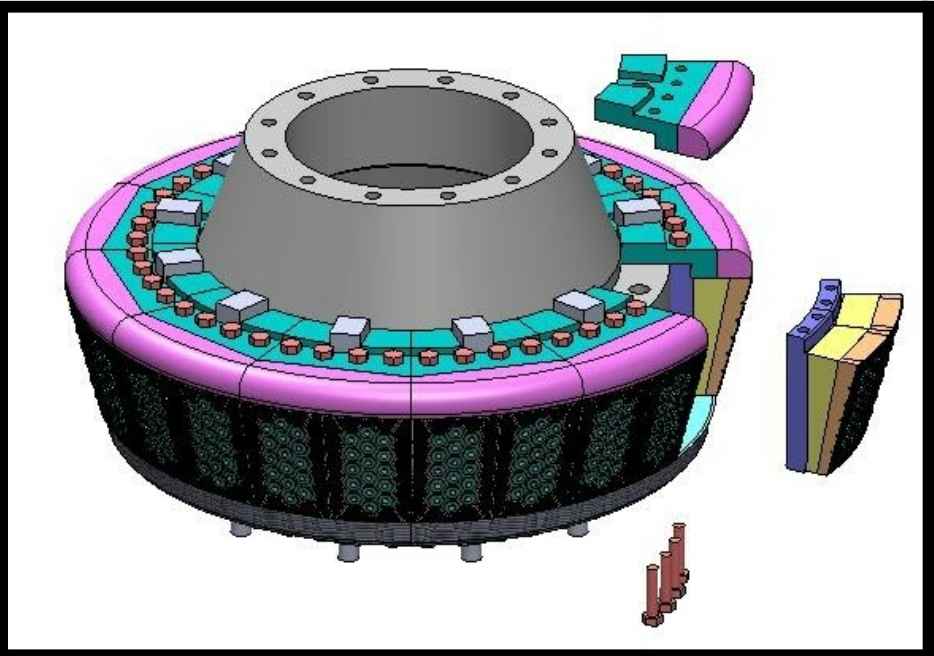

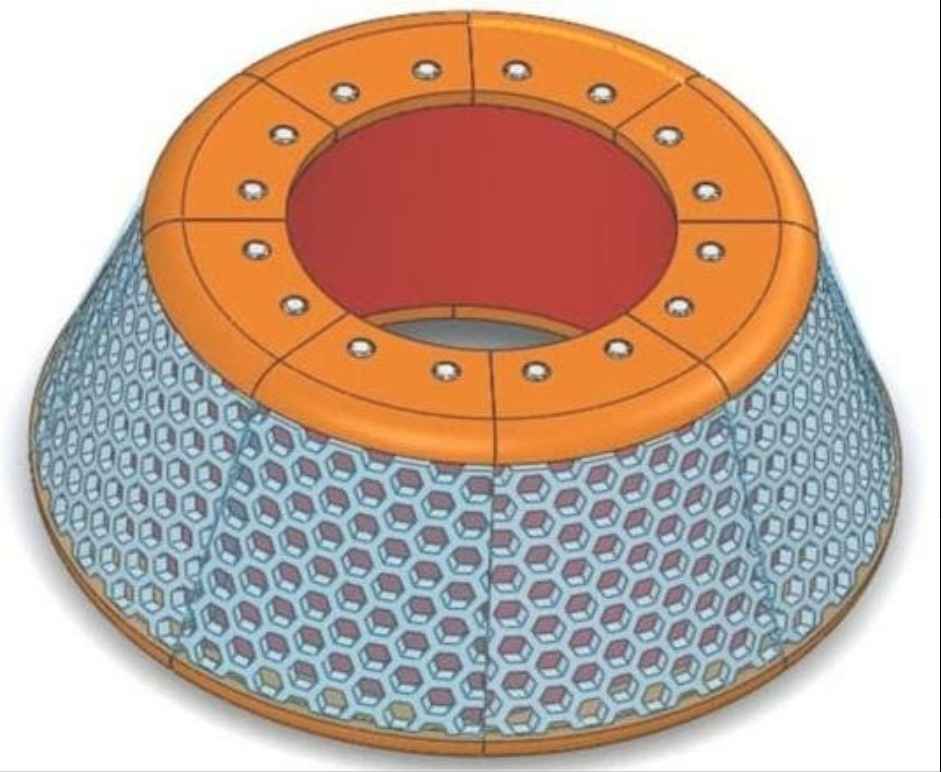

Zuper Mmcc Grinding Roller With Fully Replaceable Segments

ZUPER Metal Matrix Ceramic Composites are extremely strong abrasion resistant carbides metallurgically bonded to replaceable segments. These carbides have a minimum hardness of 770 Hv and contain carbides upto 1500 Hv most commonly used in Clinker /Limestone/ Petcoke/ Coal Plants globally.

These extremely level replicable carbides are very easy to use and can be replaced in a very short period of time. Zuper MMCC Rollers are the most cost effective VRM and Coal Mill grinding rollers in the whole world.

Our planted innovations in the metallurgy segmented make these rollers more resistant to wear as compared to traditional rollers.

Features

Properties | Measurement |

Density of Cermets | 3.5 – 4.5 g/cc. |

Ceramic Hardness: | 10 – 15 GPA Vickers hardness |

Primary & Secondary Carbide Hardness | 770- 1500 Hv |

Max working Temperature | 700 ° C |

Key Benefits

- Most cost effective solution

- Reduced Power utilization

- Most advanced Metal Matrix Carbide Composites

- Maximum Wear & Abrasion Resistance

- Can be easily retrofitted to any conventional Grinding Roll.

- Reduced weight of grinding roller tire up to 10%