Mining Products

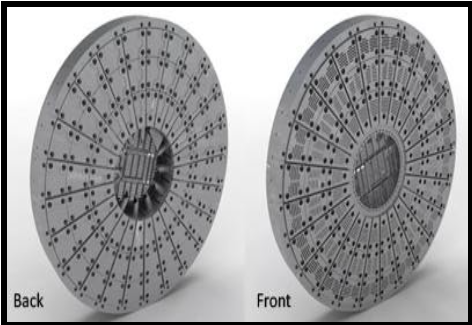

Zuper Monomer liner

Overview

Zuper Monomer liner is a high density and Ultra-wear resistance chromium carbide embedded with Zuper metal matrix ceramic composites duly fused to monomers back up plate. This gives a cushioning effect to withstand high impact and vibration effects.

The surface hardness 60-62 Hr helps to withstand the extreme abrasion, erosion wear and high temperature. Zuper monomer liners have a high impact on erosion and abrasion wear resistance. The lightweight formula has proven to reduce power consumption and an easy replacement process.

| Properties | Measurement |

| Density | 2.7 g/cc |

| Surface hardness Primary account secondary metal matrix hardness | 60-62 Hrc1200 -1500 Hv |

| Metal matrix ceramic composite hardness | 10-15 Gpa |

| Temperature range | 450-500 °C |

Key Benefits

- Light weight- Reduce weight up to 30-40% which is indirectly reducing power consumption and increasing the Efficiency of plant/ motor.

- Easy installation process due to light weight.

- Cushioning effect by Zuper Monomer to withstand high impact and vibration effect.

- High impact, erosion and abrasion wear resistance

IMCO Alloys & Co. KG © 2022

Data Protection Imprint and legal notice