Recent Posts

Recent Posts

Manual vs. Mechanical Harvesting of Sugarcane: An Agricultural Evolution

Enhancing Industrial Efficiency: The Power of Crusher Hammers

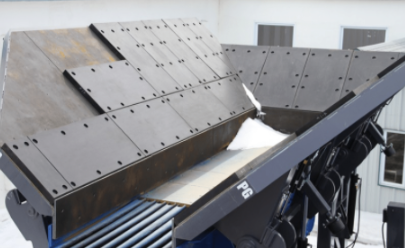

Wear Liner Plates: A Solution for Abrasion and Impact Protection

Overview

Wear liner plates are an essential component of many mining operations, as they provide protection against abrasion and impact that can cause wear and tear on equipment and structures. In this blog post, we’ll explore the role of wear liner plates in the mining industry, and how they can improve efficiency and extend the lifespan of equipment.

One type of wear liner commonly used in the mining industry is chrome carbide wear plates. These wear plates are made from a combination of chrome and carbide, which makes them highly resistant to wear and tear. They are typically used in high-abrasion applications, such as in crushers and conveyors, where they can withstand the impact of large, abrasive materials. Chrome carbide wear plates are also resistant to corrosion and can be welded onto existing equipment to extend its lifespan.

Another type of wear liner used in the mining industry is ceramic wear plates. These wear plates are made from a high-strength ceramic material, which makes them resistant to both wear and impact. They are typically used in applications where there is a risk of impact or shock loading, such as in conveyors and chutes. Ceramic wear plates are also resistant to corrosion and can withstand high temperatures, making them a good choice for use in hot environments.

A third type of wear liner used in the mining industry is rubber wear plates. These wear plates are made from a durable rubber material and are used in applications where there is a need for noise and vibration reduction. They are typically used in chutes and conveyors to reduce the impact of materials and reduce the noise levels of equipment. Rubber wear plates are also resistant to impact and wear, making them a good choice for use in abrasive environments.

In addition to these types of wear liners, there are also other materials that can be used in the mining industry, including polyurethane, steel, and composite materials. Polyurethane wear plates are made from a durable synthetic material that is resistant to wear and impact. They are typically used in applications where there is a need for flexibility and resilience, such as in chutes and conveyors. Steel wear plates are made from a strong and durable steel material and are used in applications where there is a need for high strength and durability. Finally, composite wear plates are made from a combination of different materials, such as steel and rubber, and are used in applications where there is a need for both strength and flexibility.

wear liners are an essential component of the mining industry, as they are used to protect equipment and machinery from the wear and tear of abrasive materials. There are several different types of wear liners available, each with its own set of features and benefits. Chrome carbide, ceramic, and rubber wear plates are some of the most commonly used materials in the mining industry, but there are also other materials that can be used, including polyurethane, steel, and composite materials. Ultimately, the choice of wear liner will depend on the specific needs and requirements of the application.