Revolutionizing Mining Operations: IMCO Alloys’ Cutting-Edge Approach to Wear Management

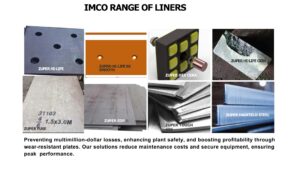

IMCO Alloys takes pride in its extensive range of liners, from conventional weld overlay plates to cutting-edge ceramic composite liners. Their commitment to innovation is evident in their claim to produce liners that surpass any others globally. This diverse range ensures that clients receive tailored solutions based on their specific needs.

One of IMCO Alloys’ standout features is their meticulous chute design, incorporating different liner arrangements. This design not only optimizes costs but also significantly extends the lifespan of the equipment. The result is a win-win situation for customers, providing both cost efficiency and increased equipment longevity.

IMCO Alloys doesn’t just stop at physical solutions; they go a step further by offering a cloud-based software solution for wear analysis. This innovative approach allows customers to track wear data in real-time, providing valuable insights into equipment performance. The cloud-based software not only enhances efficiency but is also cost-effective, catering to the pocket-friendly needs of their clients.

In a sector where wear and tear are constants, IMCO Alloys Pvt Ltd emerges as a game-changer with its Total Liner Management solution. By combining metallurgical expertise, advanced liners, optimized chute designs, and cloud-based sensors analytics, IMCO Alloys sets a new standard in wear management for the mining industry. As the go-to provider for wear solutions, IMCO Alloys is at the forefront of ensuring that mining operations run smoothly, efficiently, and with minimal downtime.