Recent Posts

Recent Posts

Manual vs. Mechanical Harvesting of Sugarcane: An Agricultural Evolution

Enhancing Industrial Efficiency: The Power of Crusher Hammers

Zuper Flat Bars Incorporate Cutting-Edge Technology & Innovation

Project Details:

• Tata Steel Kalinganagar (TSK) is India’s second integrated steel plant, manufacturing high-end flat products.

• Spread over 3,000 acres and commissioned in 2016 having a capacity 3 MnTPA.

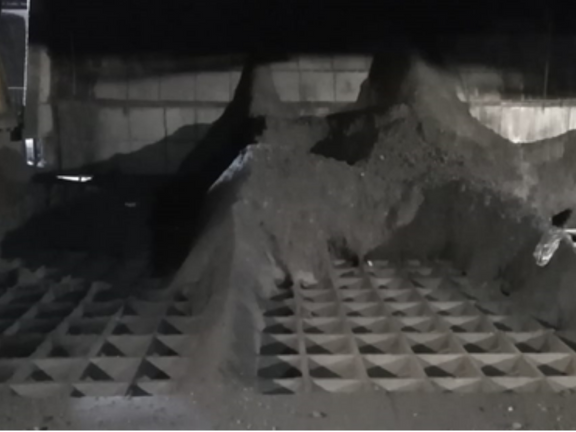

• The RMHS department having Single Wagon Tripler as subdivision had requirement of gratings for grizzly underneath the Wagon.

Application:

Requirement:

• TATA earlier they were using Hardfacing on top & side faces of appr. 3-4mm. thick having hardness 65-70 hrc after assembly

• round-off all sharp edges/corners.

• all weld joints are 8mm fillet continuous, u.o.n.

• all welding shall conform to is:9595.

• all fabrication shall conform to is:7215.

Solution :

Features of Zuper Flat Bars

• Reduced hang-ups & carry backs.

• Max Wear Resistance irrespective of direction of flow of abrasive particles.

• lower the wear rate Zuper flat bar ensures Extremely Low Residual Stress having 60-62 Hrc

• Laminar flow ensuring reduced wear

• Consistent Hardness & Micro-structure across thickness result in consistent & unmatched wear rates to lower the wear rate Zuper flat bar ensures Extremely Low Residual Stress having 60-62 Hrc