Sugar Products

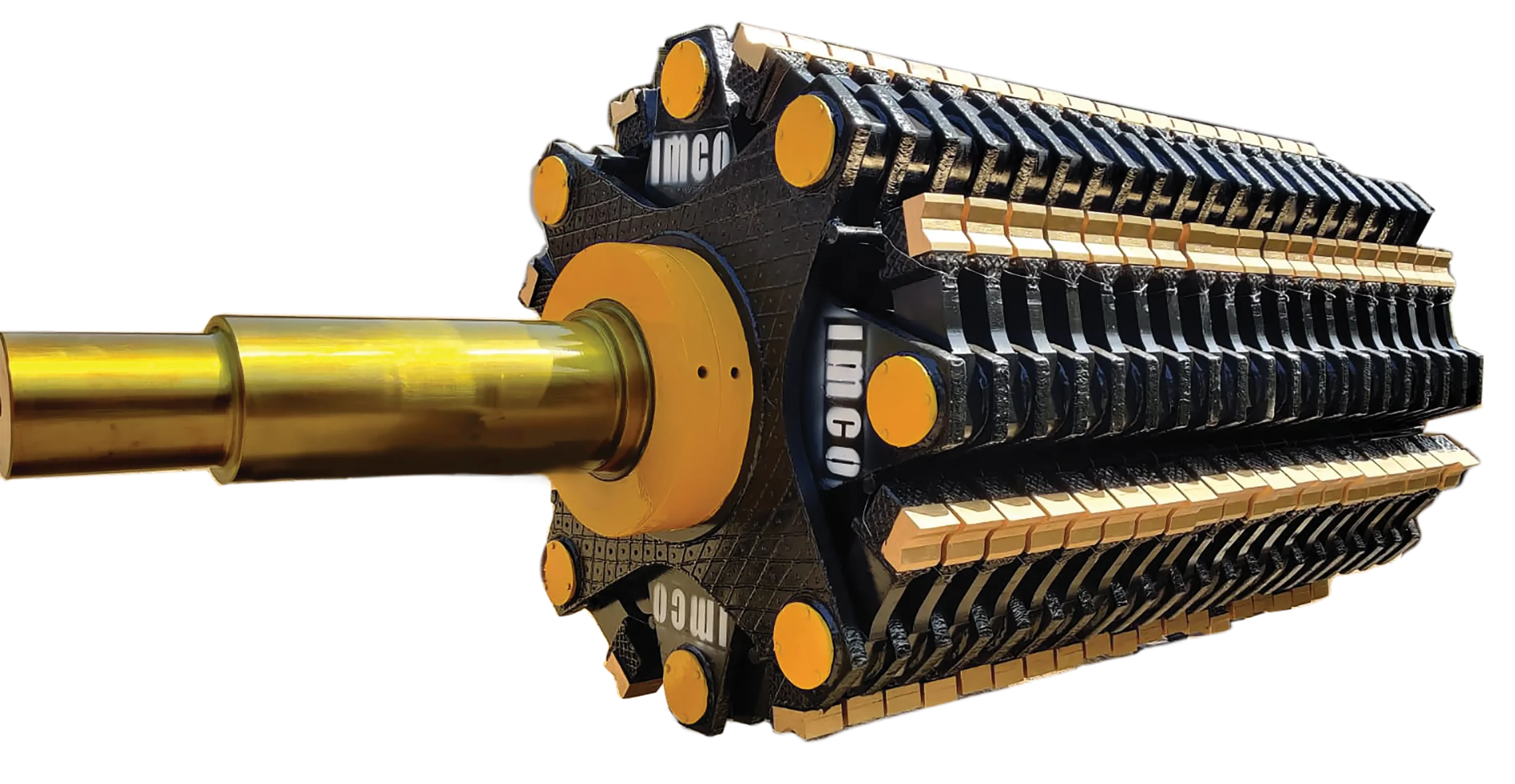

Shredders & Fibrizors

Overview

Shredders & Fibrizors are rotatory devices equipped with hammers which are used in the milling section of sugar mills worldwide. Due to the rotation and the constant hammering of the hammers, the fibers of the sugarcane are split open which enable the prepared sugarcane to be subsequently crushed in between the rollers to extract maximum juices. The RPM of a shredder depends upon the milling capacity & motor capacity.

IMCO Alloys manufacturers complete new shredders. We also offer maintenance & modification of fixed-type shredders assembly to swing type shredder assembly.

Hammers with replaceable tips

- Three / four arms type integral specially designed rotor discs eliminate failure against shocks

- Hammer shanks of fixed type leveler tenoned into machined pockets and fastened with high tensile bolts reassured a close fit, and eliminated shear. Swing hammers are hinged on axles with bush bearings. Hammers are staggered to cover the entire rotor width.

- Rotor supported in generously designed heavy-duty bearings, housed in solid cast steel bearing blocks with water cooling jacket.

- Oil mist or circulating oil lubrication forbearing.

- Anvil of pocketed construction, hard-faced to 500 BHN for improved and uniform cane preparation

- Floating flap provided over feed cane blanket achieves effective air seal and reduces excessive winding and consequently reduces noise, loss of sugar through mist formation and saves power

Key Benefits

- Enhanced cutting efficiency

- Reduced power consumption

- NO - Frequent jamming of shredder due to the swinging action of knife.

- Power consumption is reduced as each hammer develops its own inertia.

- Reduction in downtime as replacing single pins to change hammers is much quicker than replacing multiple bolts in the hammer body.

IMCO Alloys & Co. KG © 2022

Data Protection Imprint and legal notice