cement Products

Grinding Roller Tires

Overview

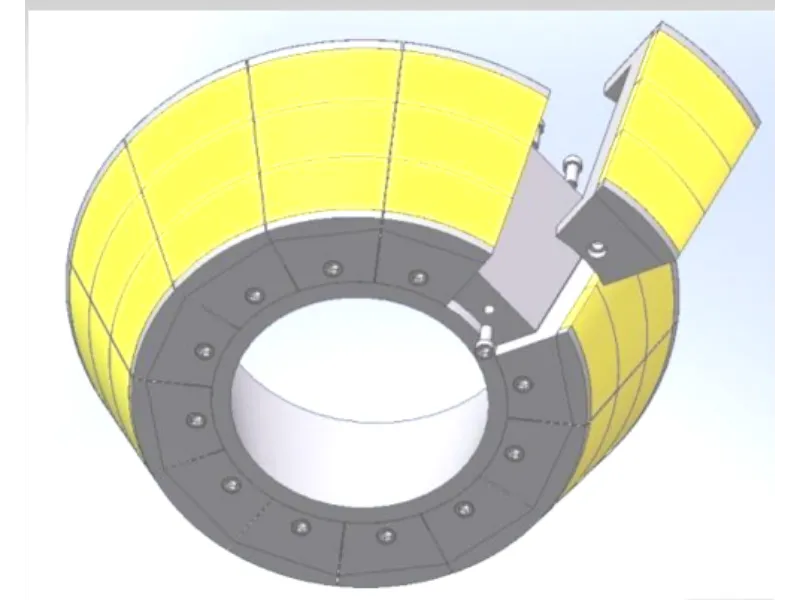

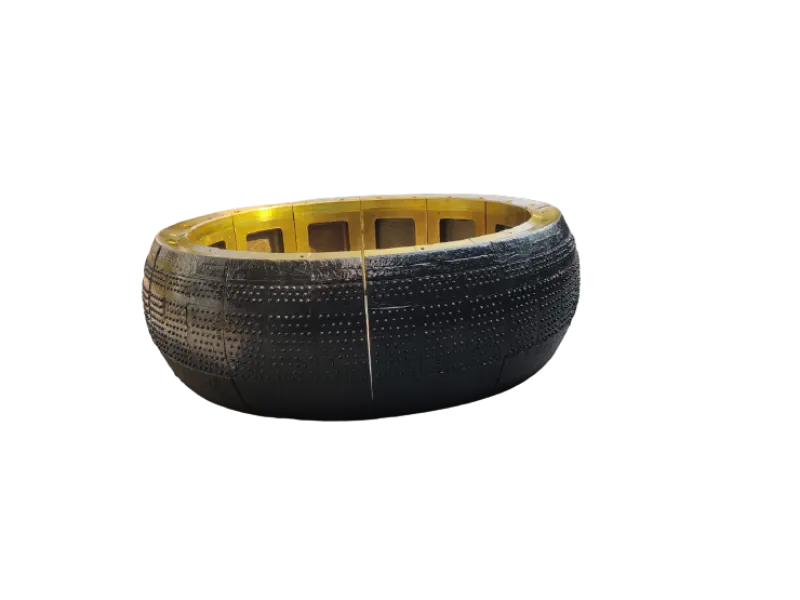

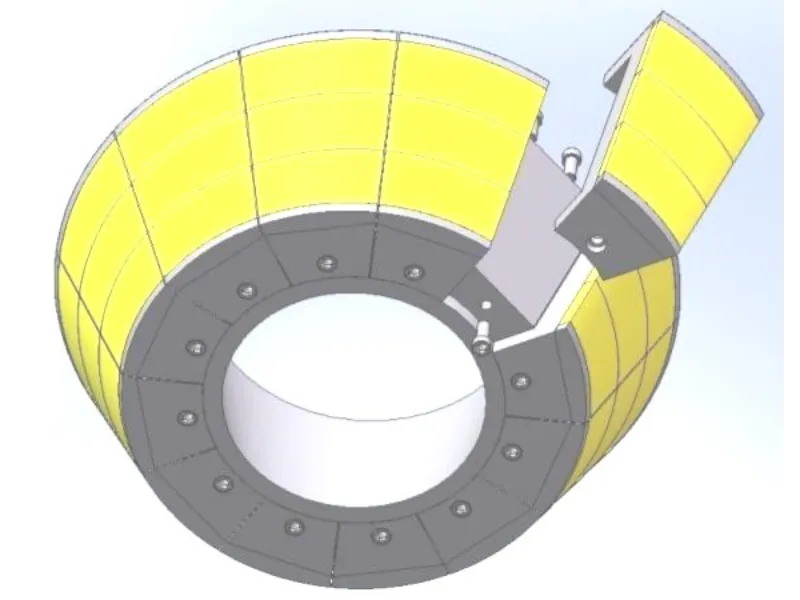

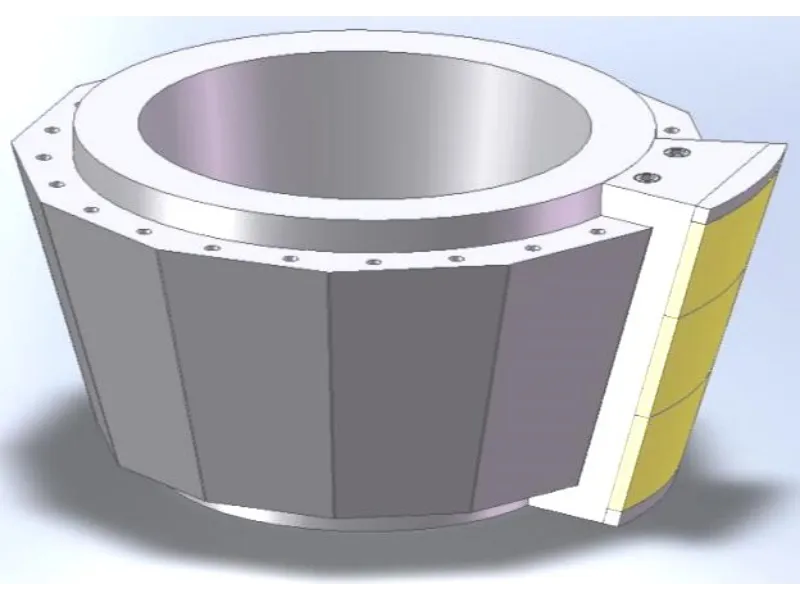

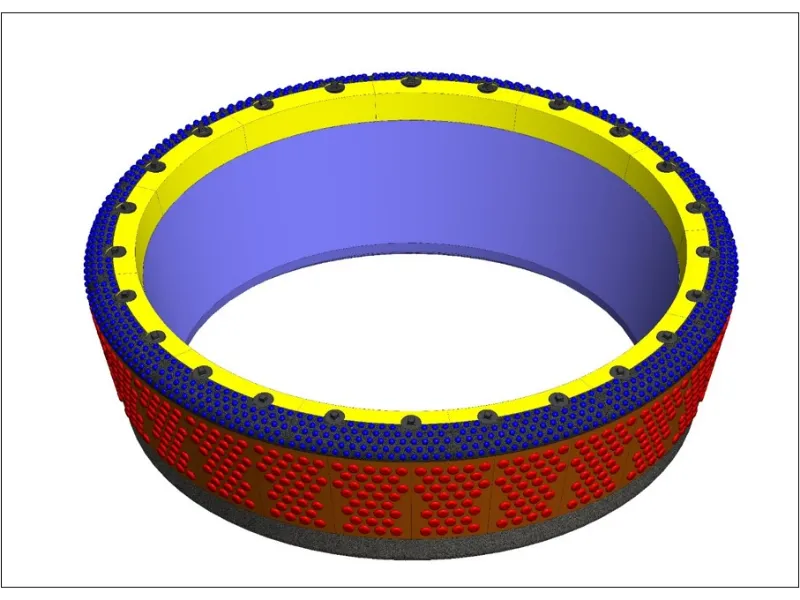

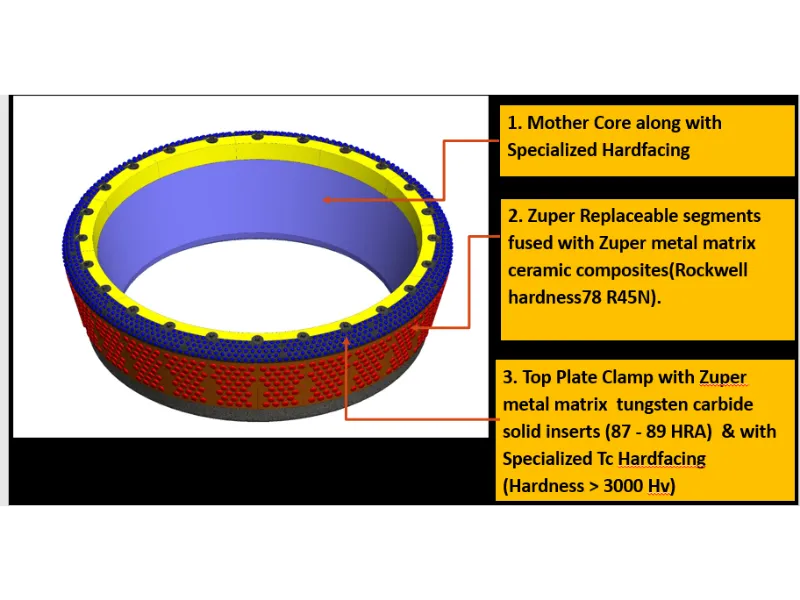

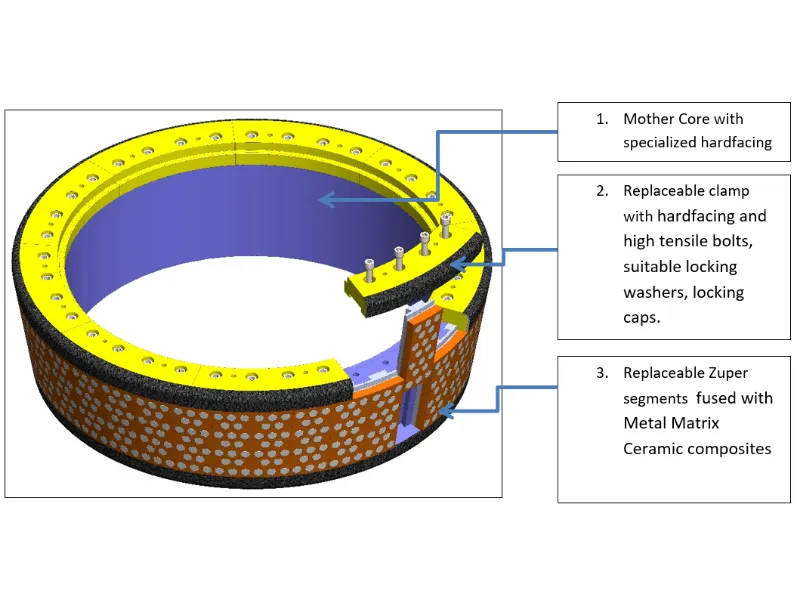

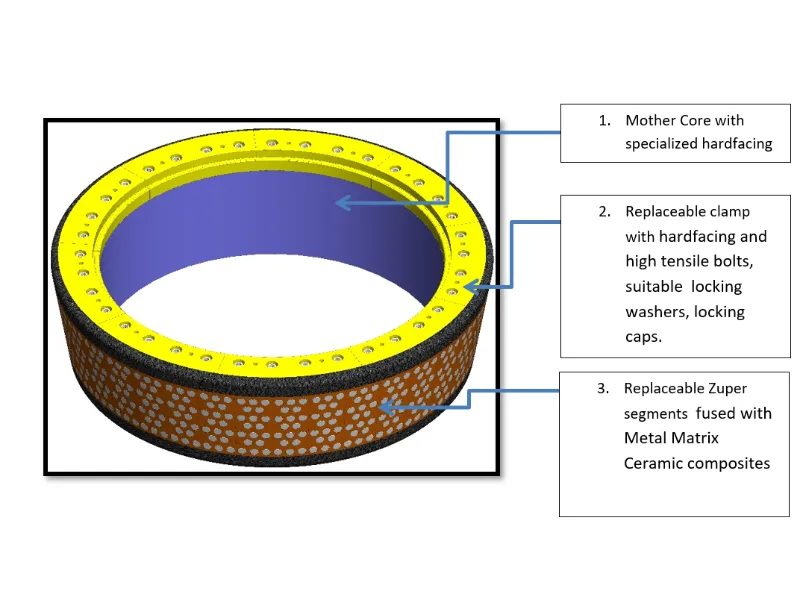

Our latest innovation, The IMCO make Grinding roller tyre is modified with Zuper replaceable segments fused with Zuper metal matrix ceramic Composites and with complete machining and finishing.

Details of parts:

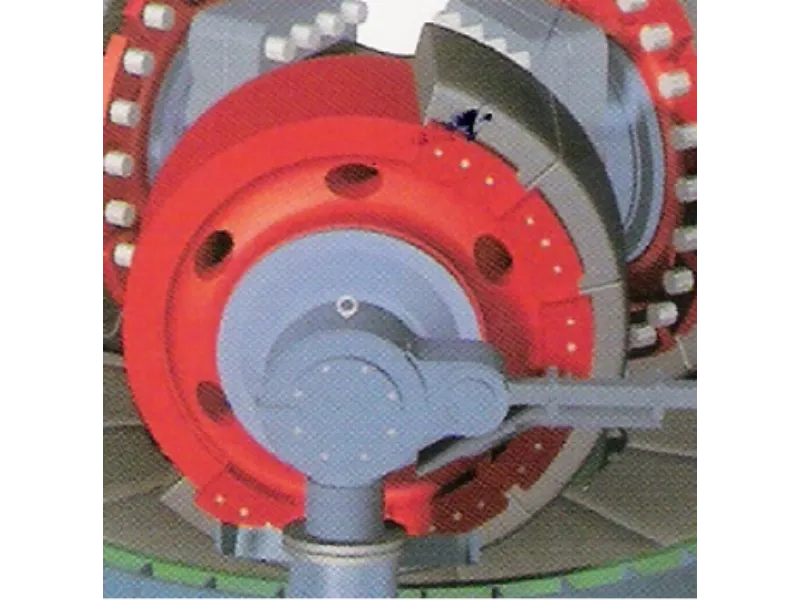

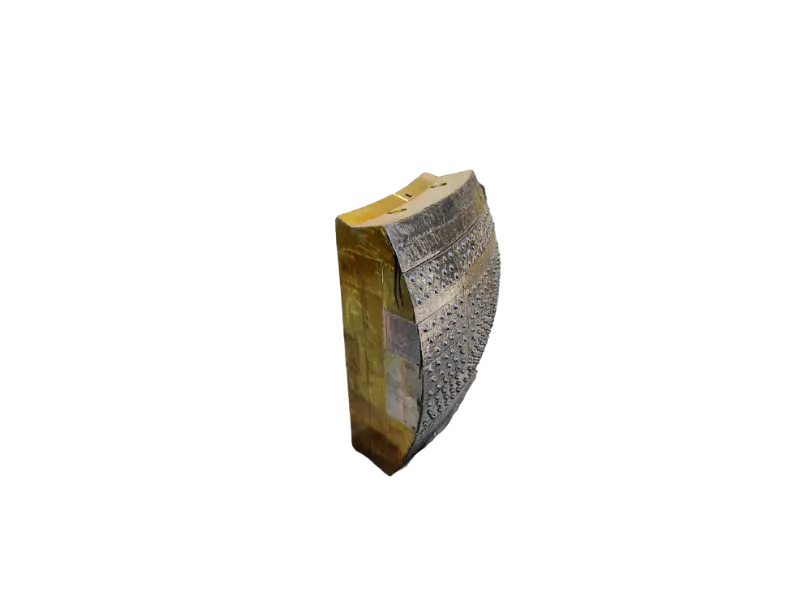

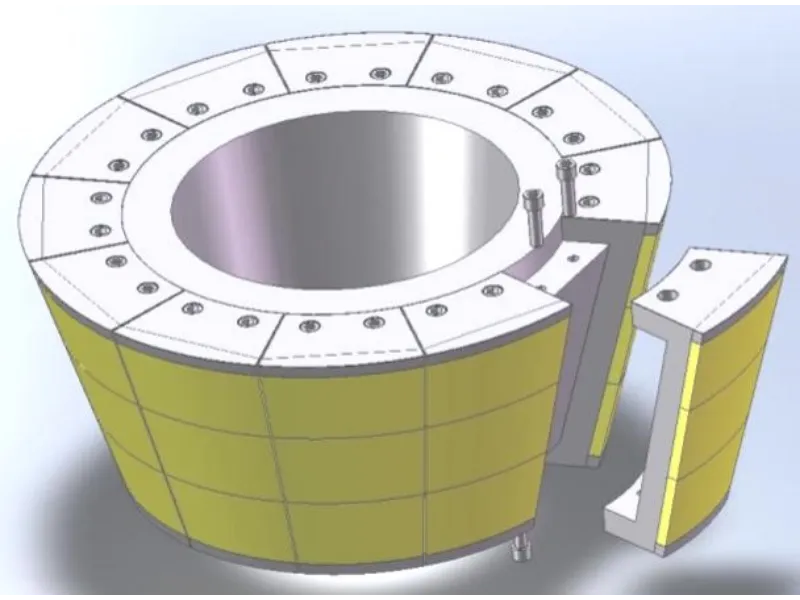

1A) Zuper MMCC grinding roller with fully replaceable segments

ZUPER Metal Matrix Ceramic Composites are extremely strong abrasion resistant carbides metallurgically bonded to replaceable segments. These carbides have a minimum hardness of 770 Hv and contain carbides up to 1500 Hv most commonly used in Clinker /Limestone/ Petcoke/ Coal Plants globally.

These extremely level replicable carbides are very easy to use and can be replaced in a very short period of time. Zuper MMCC Rollers are the most cost effective VRM and Coal Mill grinding rollers in the whole world.

Our planted innovations in the metallurgy segmented make these rollers more resistant to wear as compared to traditional rollers.

Key Benefits

- Most cost effective solution

- Most advanced Metal Matrix Carbide Composites

- Maximum Wear & Abrasion Resistance

- Can be easily retrofitted to any conventional Grinding Roll.

- Reduced weight of grinding roller tire up to 10%

- Easy replacement process. Hence reduces maintenance cost

- High efficiency in grooving

- Saves downtime and production cost

- High tensile bolt for a longer life span

Features

| Properties | Measurement |

| Density of Cermets | 3.5 – 4.5 g/cc. |

| Ceramic Hardness: | 10 – 15 GPA Vickers hardness |

| Primary & Secondary Carbide Hardness | 770- 1500 Hv |

| Max working Temperature | 700 ° C |

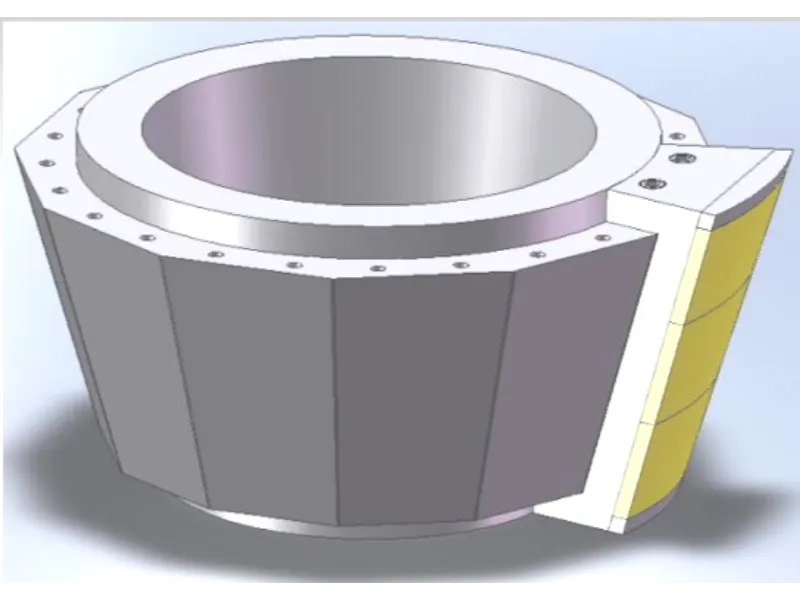

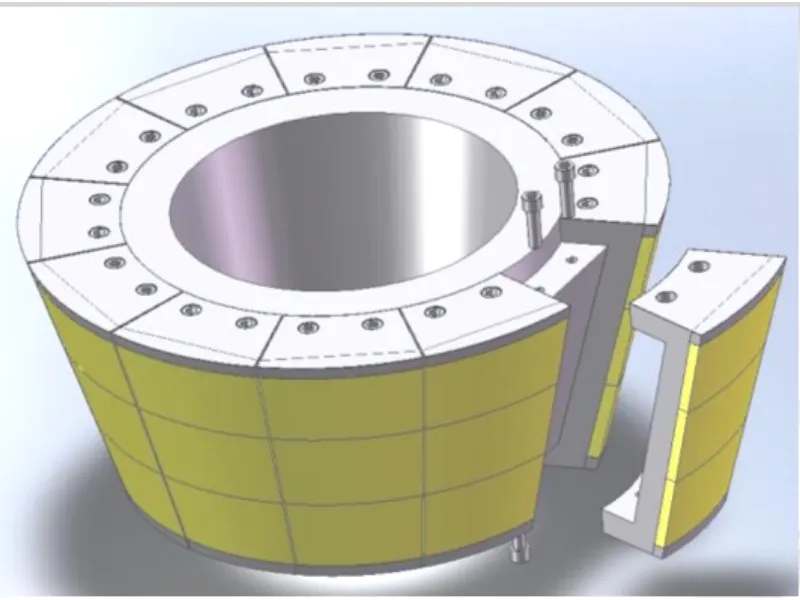

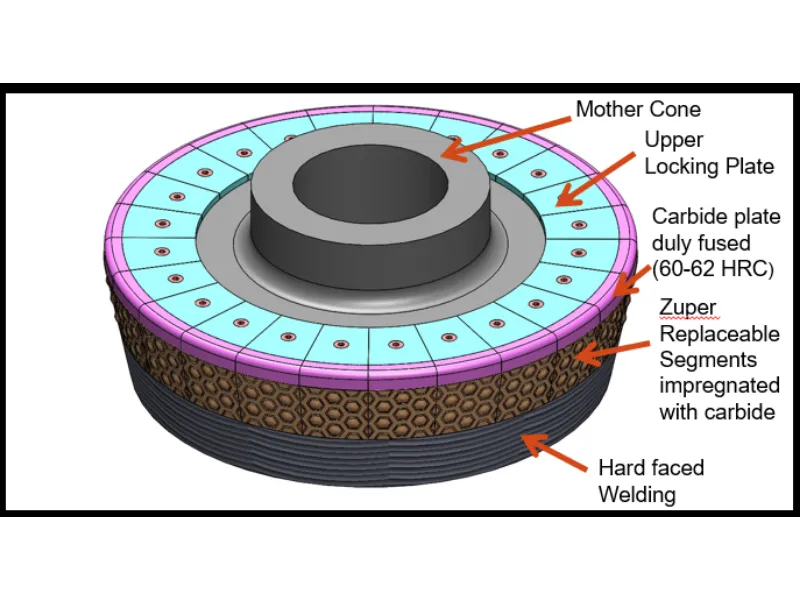

1B) – Hi Chrome Roller – Hard Carbide Layer ( Made as Per Composition )

Specialized metal matrix ceramic composites duly fused and impregnated in a sintered chromium carbides having 60-62 Hrc hardness on surface with primary and secondary carbide hardness is 790 -1500 hv and metal matrix ceramic composite hardness is up to 10-14 Gpa Vickers hardness.

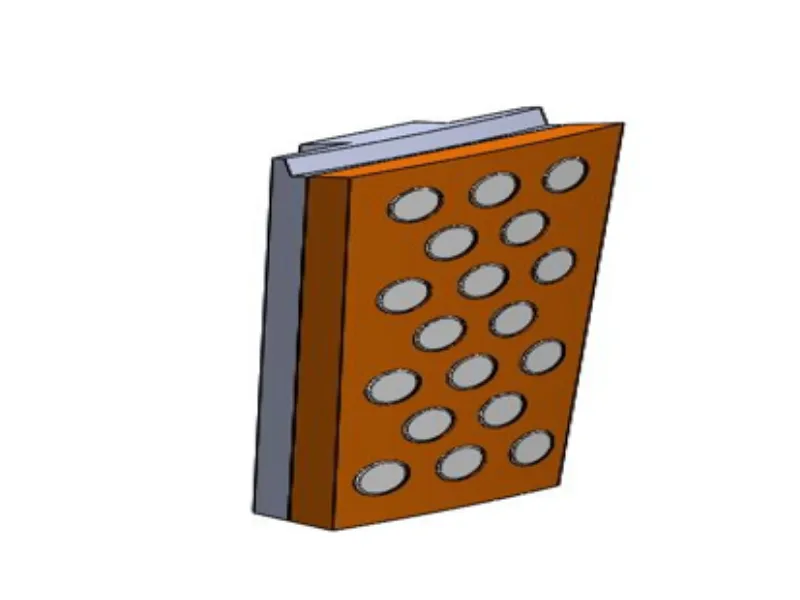

1C)- Sintered Cast Roller (Ceramic Inserts)

Top plate clamp made of base material hardened steel with hardfacing of sintered carbides having hardness of 56-60 Hrc thickness 6-8 mm fitted with high tensile bolts, suitable locking washers and locking

IMCO Alloys & Co. KG © 2022

Data Protection Imprint and legal notice