Condition monitoring systems(CAM) by Imco Alloys

We bring to you the following:

1. I & A ( Inspection & Analysis) of all critical Mill parts

Entire Mill Area including preparatory devices like Choppers ,Levellers, Fibrisors & Sugar Mill rollers .This includes Shafts & their journal Areas, Rotor bodies, Motors, Anvil , Firbizor hammers, Knife bodies, Rollers, Pinion,Liners, Couplings and other related components. The process involves a thorough inspection of the dismantled components by IMCO experts for visual, dimensional, mechanical, electrical as well as non destructive tests like IT , MPT or DPT as and where required.

2.Recommendations & report submissions:

Based on the condition of the components IMCO will submit a comprehensive report with recommendations for repair, reconditioning or replacement.

3. R&R: Reconditioning and /or Replacement job :

Based on acceptance of proposal ,Components /equipment to be reconditioned or replaced,jobs to be done at factory or IMCO’s state of the art workshop in Ambernath as required and reconditioned or new equipment to be readied for installation with dynamic balancing for rotary equipment.

4. Re-Installation of equipment:

Installation to be done by plant with supervision of critical components by IMCO experts . This includes dynamic balancing of rotary equipment after installation, checking of electricals,etc.

5. Installation & Commissioning & calibration of thresh-hold values:

Installation monitoring equipment at critical locations on the machinery and threshold limit calibrations to be done with the recommendations of the plant team over a period of one month after the plant starts running.

6. Real time monitoring at given frequency

Data will be monitored in real time over as per the threshold limits and frequencies set for each data point.

Predictive Maintenance for Rotating Equipment

Problem

- No access to real-time insights on vibration of rotors

- No access to full life cycle and remote monitoring for predictive maintenance.

- Threshold values – No real time alerts in case the threshold values are breached

- Unscheduled downtime and breakdown

Solutions

- COINs are installed on machinery from which insights are required.

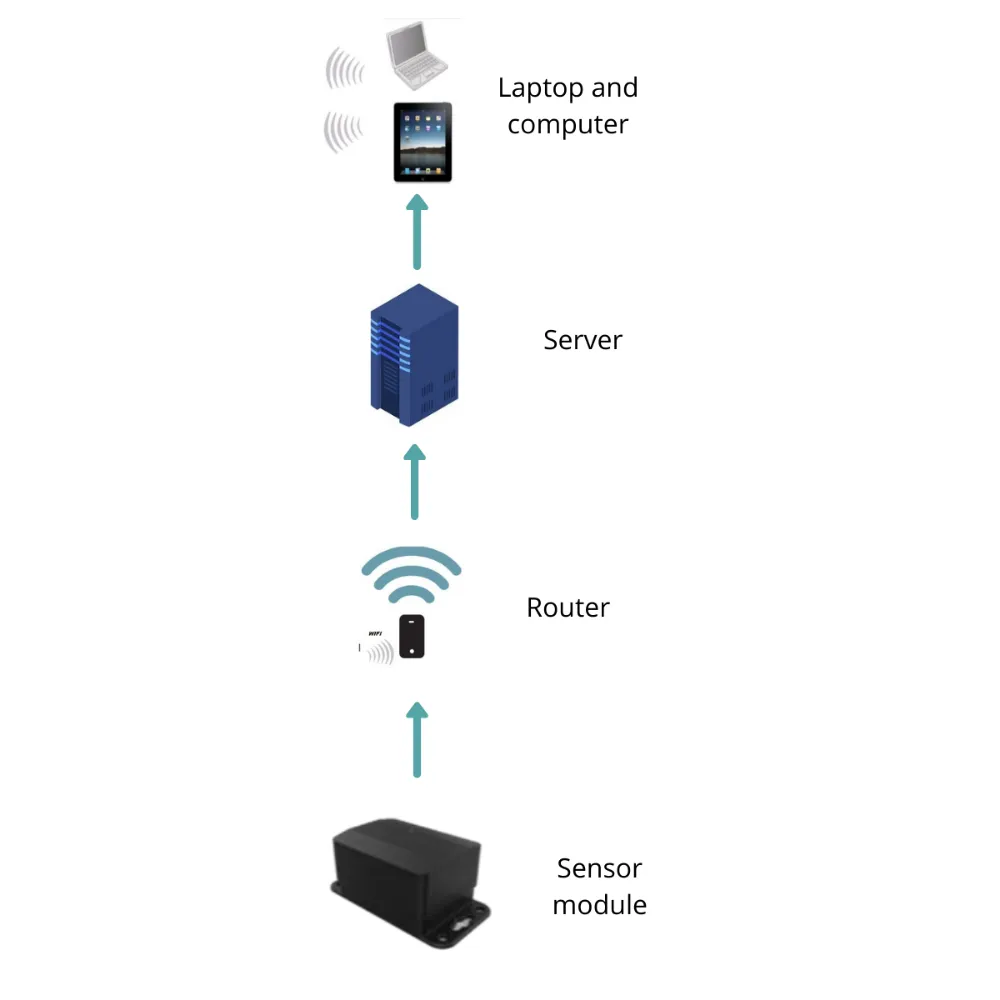

- Temperature and Vibration sensors in COIN will record any irregularities (upper and lower threshold values) at regular intervals and shares this data real-time over the cloud via our Wi-Fi or Ethernet gateway.

- The manual process of monitoring the health of machines every 15 to 20 days is eliminated using our solutions

- We can analyze historical data to identify the root cause and location of frequently occurring issues.

Benefits

- Predict asset failures in advance (FFT)

- 100% uptime without breakdown

- Periodic reports for better planning

- Higher Productivity

- Lower Operational Cost & Economical

COIN- Our Flagship Product

- Communication speed - 1 Mbps. Suitable for high speed & high data applications. Self-learning and self-healing capabilities.( out of network if the battery is down for whatever reasons the system reconnects by the shortest avl route- keeps on hunting.

- Self Healing- the coin that was down will start and hunt and self heal on its own.

- Range - 180 ft per node max subject to interference. Range increases with more nodes in the mesh. ( coin to coin is node to router) if coins are not able to connect to the gateway the additional coin will act as a booster.

- Machine learning and edge computing on every node. Studying vibration patterns to formulate with algorithms will keep on comparing and if the difference is within range). Edge computing is a processing happening on every coin – load . This reduces lag.

- D type battery

Advantages of Condition & Monitor

- Avoid breakdown.

- Predict failures in advance.

- Get periodic reports for better planning.

- Get higher productivity.

- Lower operations and maintenance cost.

- Keep your plant perfect.

| Benefits | Features | Advantages |

| No Need of Maintenance, Calibration | Calibrated for life | No downtime, No periodic service |

| Readings in Deg Celsius or Fahrenheit | Units as per your needs | Easy readings |

| No data Loss in case of power down | COIN + Gateways has onboard flash memory | Always stay connected to machines |

| Wide Temp. range of operating conditions across winter/ summer | Temp from -40 to +80 Deg C | Any existing + other machines operating in other conditions can be covered. |

| % RH wide range in Winter & summer | % RH from 0-95% | Any existing + future machines can be covered ( RH will be measured within an area covering 1-3ft in radius from the sensor). |

| Will cover all your vibrations patterns | Vibration – from 0 to 16 g (m/s2) available, can give Velocity, Displacement, Acceleration | No need to have additional sensors/ Hardware ( velocity of vibration (time required),displacement ( height of the vibration),Acceleration (G value) |

| Always up to date software | Can be updated via internet Hardware has onboard microprocessor + | Cutting edge technology in Industry 4.0 |

| Remote connected | Hardware has onboard microprocessor + Networking ability |

Deliverables

- Separate account with Login + Password

- Browser based access to multiple devices

- Cloud Storage

- Cloud Analytics.

- SMS, Email notifications as per threshold

- Every end of the day automatic report.

- Remote technical support

- User settable threshold setting etc.

Sensor

- No calibration or maintenance required.

- Easy readings.

- Wide operating temperature

- Great communication speed.

- Wide range of humidity monitoring.

- Covers all vibration patterns (velocity displacement and acceleration)c

- Software update is easy- no shutdown required.

- Latest technology ( Industry 4.O)