Wear Resistant Coating

Protecting Your Investments

IMCO Coating and Lining Solutions provides factory and site based specialist coating solutions to the oil, gas,chemical, refinery, water and wastewater treatment, power, construction,

Infrastructure industries.

With experience in managing and controlling corrosion in some of the toughest and most critical environments in the world we know how to tackle the engineering management and implementation of the best corrosion control systems to keep your facility on track.

Whether it be pipelines, process vessels, storage tanks, offshore structures or chemical treatment areas, IMCO offers the most efficient solutions designed to meet specific needs of the

Industry and includes the applications of the following specialized technology.

Range:

- Solvent Free Epoxy and Polyurea,

- Polyurethane Systems.

- Glass Flake Reinforced Polyester / Pure

- Epoxy System / Vinyl Ester

- Thermal Metal Spray – Zinc / Monel

- Aluminum / Stainless Steel

- Ceramic Linings and Coatings

- Abrasive Blasting

- High Temperature Coatings

- Corrosion Mitigation And Management

1. Coatings And Linings Technology Range

Solvent Free Epoxy And Polyurea, Polyurethane Systems

Plural component hot applied coating is the modern, fast, efficient and reliable method for the factory application of high performance materials to critical pipelines and equipment. Also favored as a field rehabilitation and field joint coating system because of its tough, abrasion resistance capability, pipe can be bedded and backfilled almost immediately after

completing which is of vital importance to the timely completion of fabrication and rehabilitation projects. IMCO offers a complete factory and field service for both new and existing equipment and pipelines.

Typical Applications:

External Buried Pipelines, Pipeline Field Joints, Bends valves etc

Water / WasteWater Treatment Plants, Potable Water Reservoirs

Cooling Towers Basins, Building WaterProofing etc

Typical Applications:

Internal Pipe Spools / Bends / Fittings / Valves

Internal Separator Vessels

Seawater Intake Lines / Absorbers / Scrubbers

High Chemical Resistance

2. Glassflake Reinforced Polyester / Pure Epoxy System / Vinyl Ester

Glass flake coatings and linings are widely used in situations of extreme chemical and abrasion environments. Based on polyester, vinyl ester or bisphenol or epoxy resins, heavily loaded with mica chip, they provide a tough and extremely durable to even the most arduous of service conditions. These linings can be both factory and field applied by IMCO qualified installers.

Typical Applications:

- Internal Pipe Spools / Bends / Fittings / Valves

- Internal Separator Vessels

- Seawater Intake Lines / Absorbers / Scrubbers

- High Chemical Resistance

3. Thermal Metal Spray – Zinc / Monel /Aluminum / Stainless Steel

The electric arc and flame spray application of exotic metal coatings is rapidly becoming more and more popular world-wide for the long term protection of steel surfaces against extreme marine, high temperature and corrosive chemical environments, especially for areas where extended life to first maintenance is essential

IMCO offers a complete factory and field installation service employing the most modern of techniques and equipment enabling rapid and economical production. Flame sprayed deposition represents one of the highest integrity coating systems available on the market today.

Features:

- Extreme Corrosion Resistance

- Excellent Chemical Resistance

- High Temperature Resistance

- Extremely Durable – Extended Service Life

Typical Applications:

- Splash-zone Area of Riser Pipes / Jacket legs / Conductors

- External Pipe Spool / Valves / Fittings / Bends

- External Steel Flare Booms

Bridges - Structural Steel Members

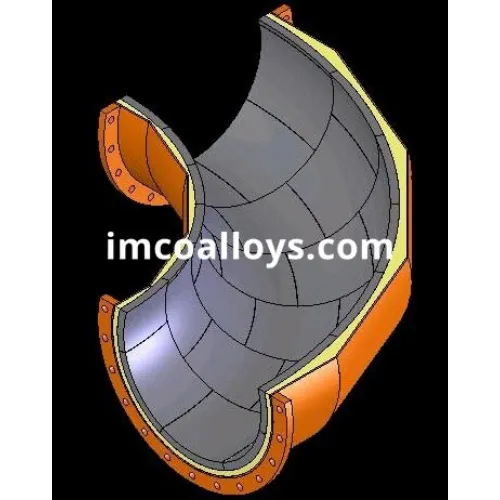

4. Ceramic Linings And Coatings

With the near diamond hardness of alumina oxide and ceramic composites, we are now able to extend the life of processing equipment 10-15 times over the past standard technology. Ceramic lining had become the standard best practice of coal processing and related operations to maximize return on investments. Coal processing operations realize huge returns with use of our Ceramic Lining Technology.

Typical of ZuperCrete:

- Quick Dry

- Quick Return to Service

- Single Coat Protection

Features of ZuperCrete:

- Chemical bond with substrate not just a layer.

- Single Coat Protection

- Dual Component Spray

- Passivation Layer

- Abrasive Blasting

5. Abrasive blasting

The team at IMCO has the ability, expertise and equipment to produce abrasive blast surface in severely corroded and pitted confined spaces and of new steel surfaces in a time bound manner. This includes but is not limited to preload tanks, mud pit tanks, void tanks and spaces, potable water tanks, diesel oil tanks and many more.

Our Capabilities

Garnet Blasting

Grit Blasting

Shot Blasting

Glass Bead Blasting

Wet Abrasive Blasting

6. Corrosion Mitigation And Management

Your production or processing facility may be relatively new, or it may have been operating for a number of years. It will have been well engineered and constructed and is doubtless generally well maintained. There will be parts of your facility however, that might be considered the “heart” of the manufacturing or processing that by the very nature of their function endure some of the most severely corrosive environments imaginable.

These are the “wear parts” of your Industry. IMCO offers services ranging from

Inspection

Condition Assessment and Evaluation

Specification Preparation

Project Management

Project Implementation including specialist coating lining services

7. Flaker Drum Restoration

Flaker Drums are used to convert molten chemicals into solid flakes. This is achieved by forming a thin layer of molten product on the outside surface of a rotating drum and causing this to be solidified by spraying cooling water from the inside surface of the drum. An adjustable scrapper continuously removes the solidified material from the drum surface in flake forms.

To keep up the quality of the flakes produced, the condition of the drum plays an important role. IMCO carries out thermal spraying on worn out Flaker Drums to give the component an enhanced service life.

Flaker Drum Rebuilding

Thermal Coating

Onsite grinding

Abrasive Blasting

Advantages of Thermal Spray :

Cost Effective

Large Build ups

Low heat application

Economic Application for:

Dimensional Restoration

Wear Resistance

Heat protection

Corrosion protection

7. Conveyor Screw Rebuilding

Screw conveyors are used for bulk movement of materials. They can be applied to numerous industrial or commercial applications including Paper mills, Pharmaceutical, food production, refineries, etc, for either recovery or removal purposes, or to waste flows to convey separated screened solids.

These conveyors come in contact with materials that are toxic, abrasive and sticky.

To keep up the quality of the material conveyed, screws in the conveyer play an important role. IMCO carries out thermal spraying on worn out screws to give the component an enhanced service life.

Advantages of Thermal Spray :

Cost Effective

Large Build ups

Low heat application

Economic Application for:

Dimensional Restoration

Wear Resistance

Heat protection

Corrosion protection

IMCO provides the following services on the above:

Screw Rebuilding

Thermal Coating

Rebuilding of profiles for variety of screw shapes

Onsite grinding

Dynamic Balancing

Markets We Protect

Waste Water Treatment Storage Tanks, Aeration Tanks, Clarifier Tanks, Digesters Sewer Pipelines, Structural Steel Dewatering Tanks, and many more.

Marine Ballast Tanks, Gas Scrubbers, Sluice Valves, Sluice Gates, Pontoons, Shafts, Oil Coolers, Rudder Stacks, and many more..

Oil And Gas Offshore Rigs, Process Vessels, Stacks, Mud Tanks, Condensers Acid Storage, Brine Pods, Pipelines, and many more..

Industrial Plants Reagent Storage, Transformers White Liquor Tanks, Pump Casings, Effluent Pipeline, Cooling Tower, DM Plants, and many more..

Infrastructure Bridges, Steel Structure, Rail Wagons, Transport Vehicles, WTPs, STPS, Fireproofing, and many more..